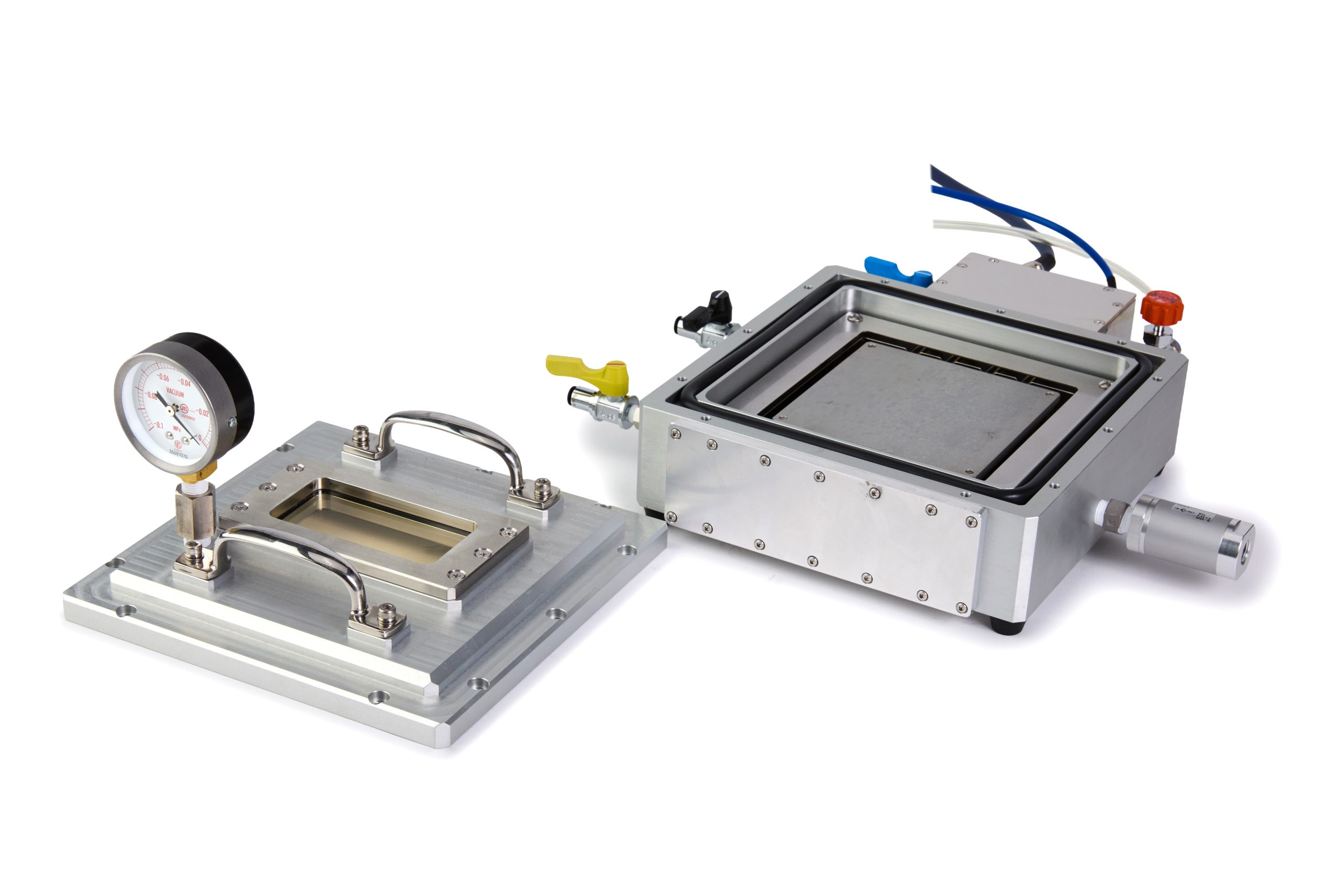

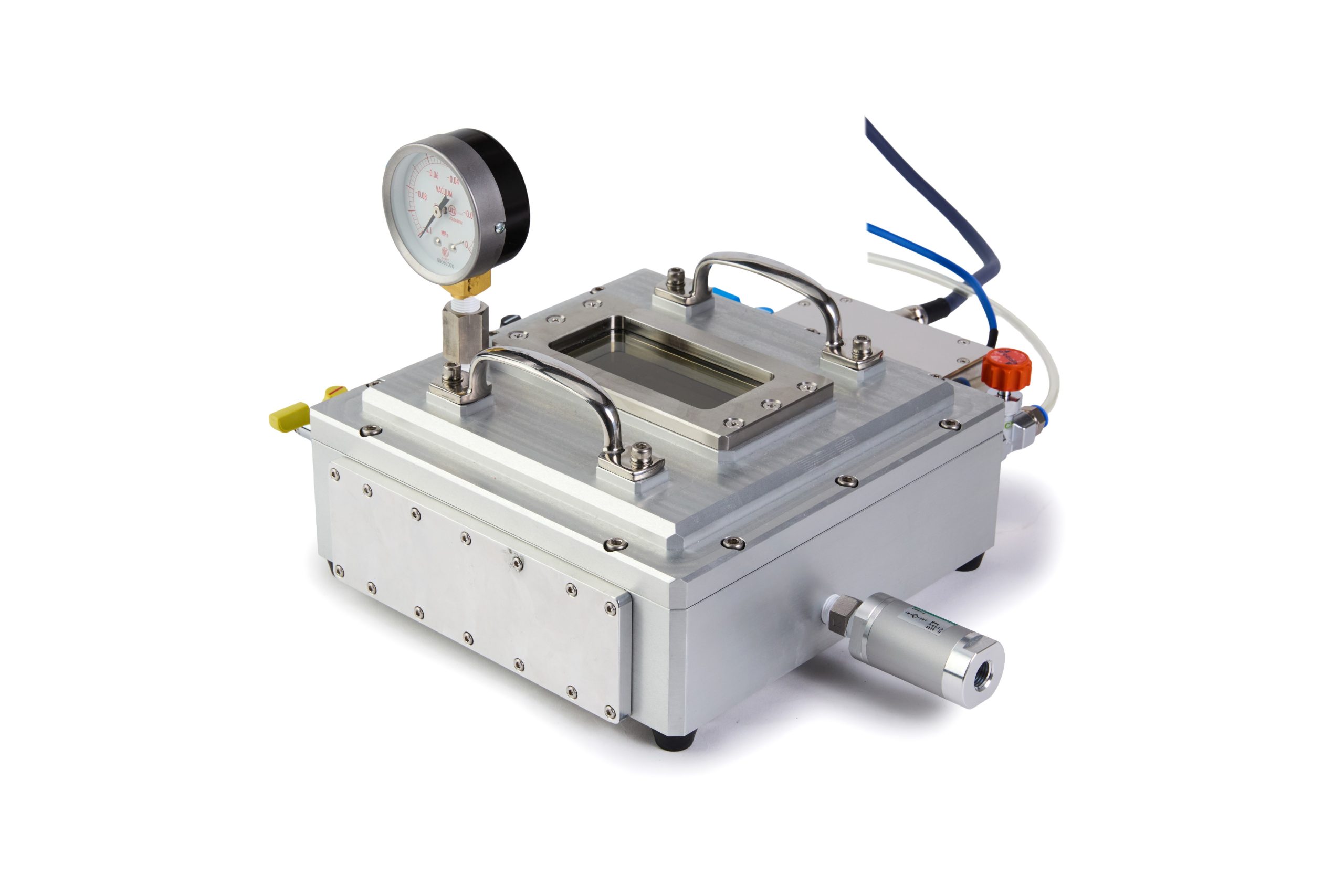

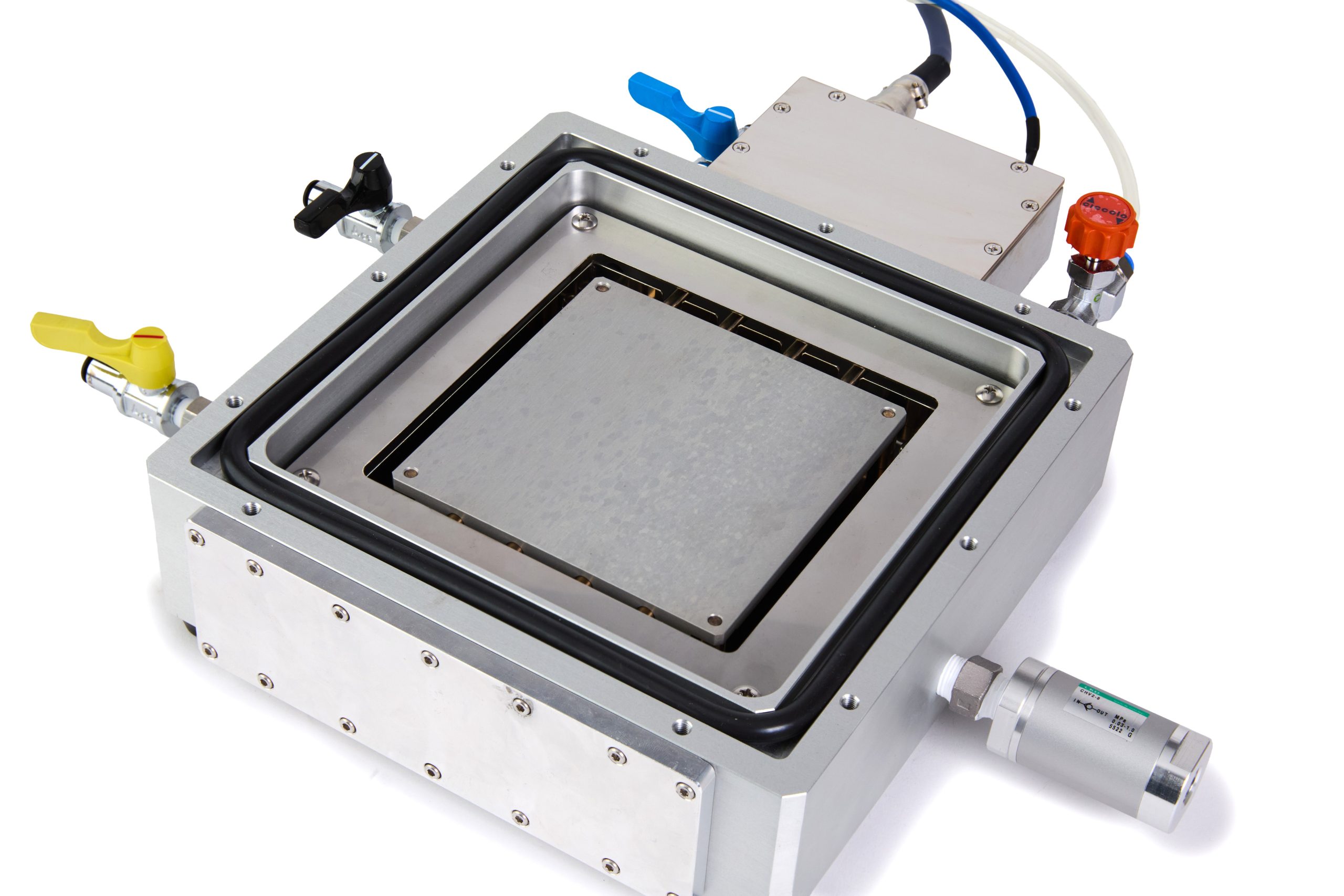

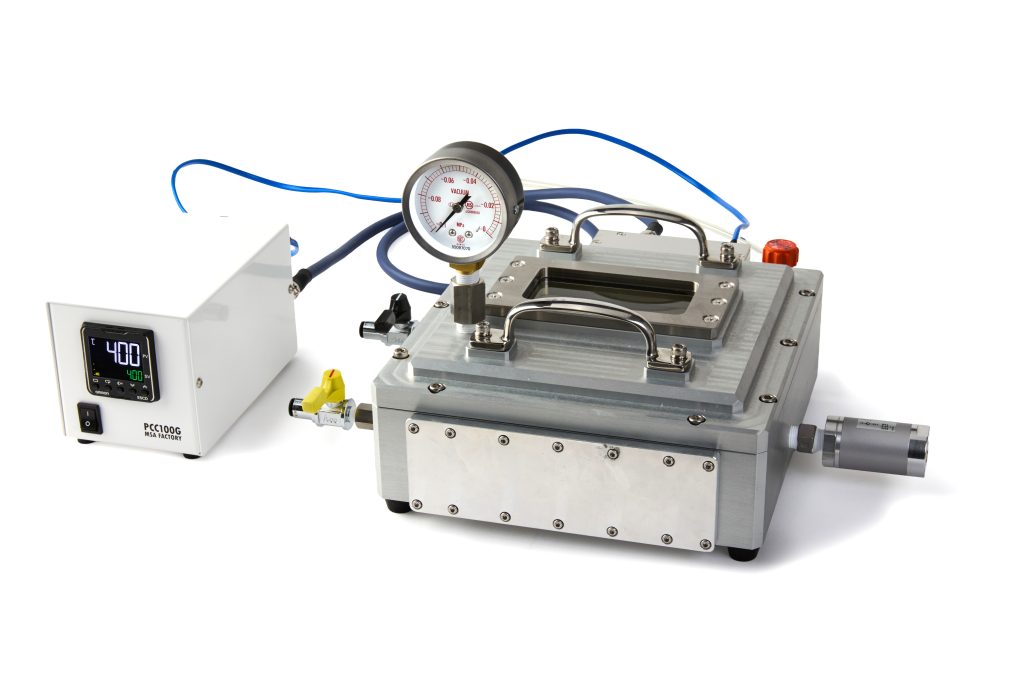

Vacuum hot plate chamber PH222 Max. temperature 800°C

Main applications

The vacuum oven can be used as a laboratory apparatus for vacuum heating, vacuum baking, and vacuum drying. It can be used to construct a vacuum heating process at a low cost.

MSA FACTORY HEATING KNOW-HOW

We combine a variety of expertise in materials (super heat-resistant plates, heat distortion countermeasures) heater design, heat insulation, thermal radiation, etc.

Simple main unit + abundant options for a variety of applications

Special specifications are available for temperatures up to 800°C.

The simple configuration allows you to build high temperature and vacuum processes. In addition, with a wide range of options and customization options, you can build the model that is best suited to your company.

high efficiency

Uniform heating is possible due to hot plate heating. Workpiece processing time is also short, and we invite you to compare the time with conventional processes.

safety

Optional safety functions such as overheating monitoring, earth leakage detection, and load disconnection can be added to the controller.

augmentability

A wide variety of options are available. By selecting these options, you can configure the equipment to meet your objectives. For details, please refer to the options column of the model list below.

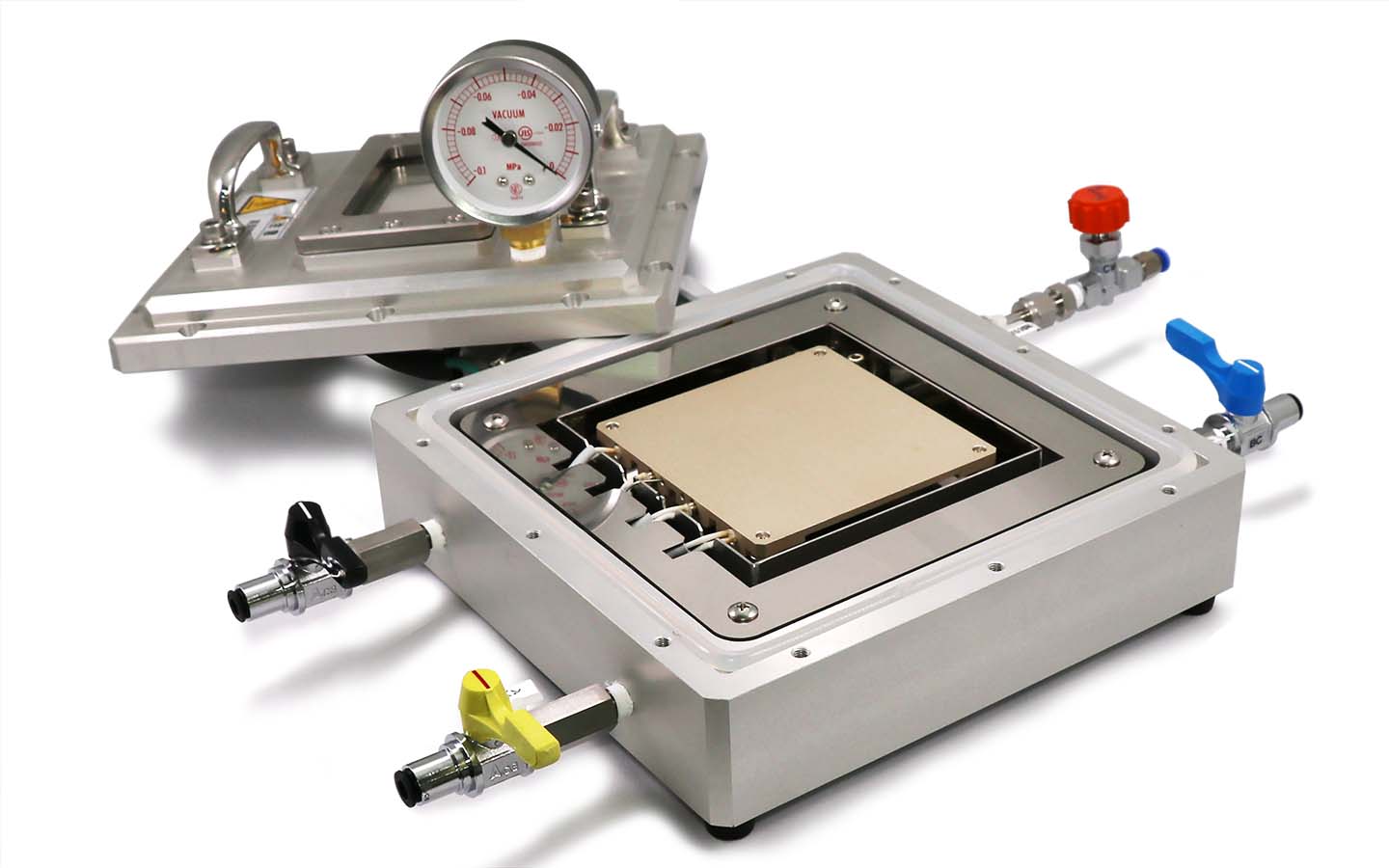

New! Product for organic solvent gas and siloxane outgas / PH222-F

The PH222-F, a model with reduced outgassing in vacuum environments, is also available as part of the series.

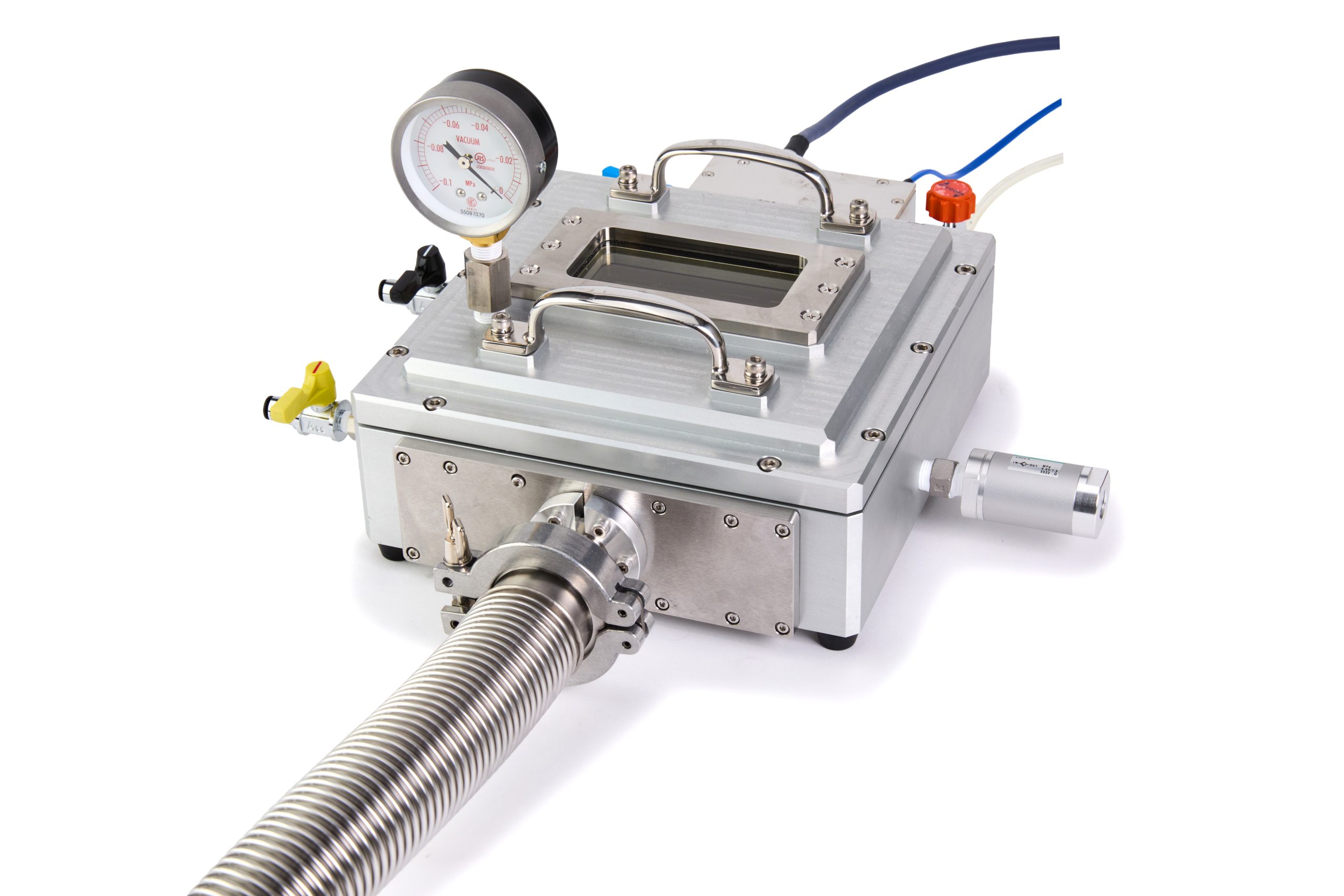

In addition to products compatible with organic solvent gases and siloxane outgassing, KF flange contact for vacuum flexible cable / PH222-K

KF flange replaces one-touch contact - vacuum pump

Model list ① PH222 series Standard

|

|

|

|

|---|---|---|---|

model number |

PH222 |

PH222-50 |

PH222-Cust |

Max. temperature |

400℃ | ||

Supported vacuum pressure |

Approx. 100 Pa *Depends on the pump used | ||

Plate size |

100 x 100mm | 50 x 50mm | 150 x 150mm |

Plate Material |

aluminum alloy | ||

Supply voltage |

AC100V | ||

Compatible Temperature Controller |

PCC107-FL、PCC100Gシリーズ等 | ||

forte |

Manual Vacuum Hot Chamber | Custom-made type | |

controller |

|

||

option |

Water-cooled unit for long-time operation, vacuum sensor (gauge pressure), vacuum gauge (Pyrani gauge), external signals, feedthroughs for power supply, sensors for temperature monitoring, etc. | ||

Model List (3) PH222 Series Ultra High Temperature

|

|

||

|---|---|---|---|

model number |

PH222-600 |

PH222-800 |

|

Max. temperature |

600℃ |

800°C (water-cooled standard) |

|

Plate size |

100 x 100mm | 50 x 50mm | 150 x 150mm |

Supported vacuum pressure |

Approx. 100 Pa *Depends on the pump used | ||

Plate Material |

heat-resistant alloys | ||

Supply voltage |

AC100V | ||

Compatible Temperature Controller |

PCC107-FL、PCC100Gシリーズ等 | ||

forte |

Manual Ultra High Temperature Vacuum Hot Chamber | ||

controller |

|

||

option |

Water-cooled unit for long-time operation, vacuum sensor (gauge pressure), vacuum gauge (Pyrani gauge), external signals, feedthrough for power supply, sensor for temperature monitoring, exhaust trap (for low melting point materials), etc. | ||

Model List (3) PH222-F Series New!

|

|

|

|

|---|---|---|---|

model number |

PH222-F New! |

PH222-F-600 New! |

PH222-F-800 New! |

Max. temperature |

400℃ |

600℃ |

800°C (water-cooled standard) |

Plate size |

120 x 120mm | 120 x 120mm | 120 x 120mm |

Supported vacuum pressure |

Approx. 100 Pa *Depends on the pump used | ||

Plate Material |

heat-resistant alloys | ||

Supply voltage |

AC100V | ||

Compatible Temperature Controller |

PCC107-FL、PCC100Gシリーズ等 | ||

forte |

The structure is designed to be siloxane-free, eliminating the generation of organic gases. All heaters and sensors are enclosed outside the vacuum environment. |

Same features as above, but with water cooling for 800°C operation | |

controller |

|

||

option |

Water-cooled unit for long-time operation, vacuum sensor (gauge pressure), vacuum gauge (Pyrani gauge), external signals, feedthroughs for power supply, sensor for temperature monitoring, exhaust trap (for low melting point materials), etc. | ||

Model List (4) PH222-K Series New! High-Definition & High-Vacuum

|

|

|

|

|---|---|---|---|

model number |

PH222-K New! |

PH222-K-600 New! |

PH222-K-800 New! |

Max. temperature |

400℃ |

600℃ |

800°C (water-cooled standard) |

Plate size |

120 x 120mm | 120 x 120mm | 120 x 120mm |

Supported vacuum pressure |

Approx. 10 Pa *Depends on the pump used | ||

Plate Material |

heat-resistant alloys | ||

Supply voltage |

AC100V | ||

Compatible Temperature Controller |

PCC107-FL, PCC100G, etc. | ||

forte |

KF flange connection for high vacuum. Siloxane-free construction eliminates organic gas generation. Heater and sensors are all disconnected from the vacuum environment. |

Same features as above, but with water cooling for 800°C operation | |

controller |

|

||

option |

Water-cooled unit for long-time operation, vacuum gauge (Pirani gauge), external signals, feedthroughs for power supply, sensor for temperature monitoring, exhaust trap (for low melting point materials), etc. | ||