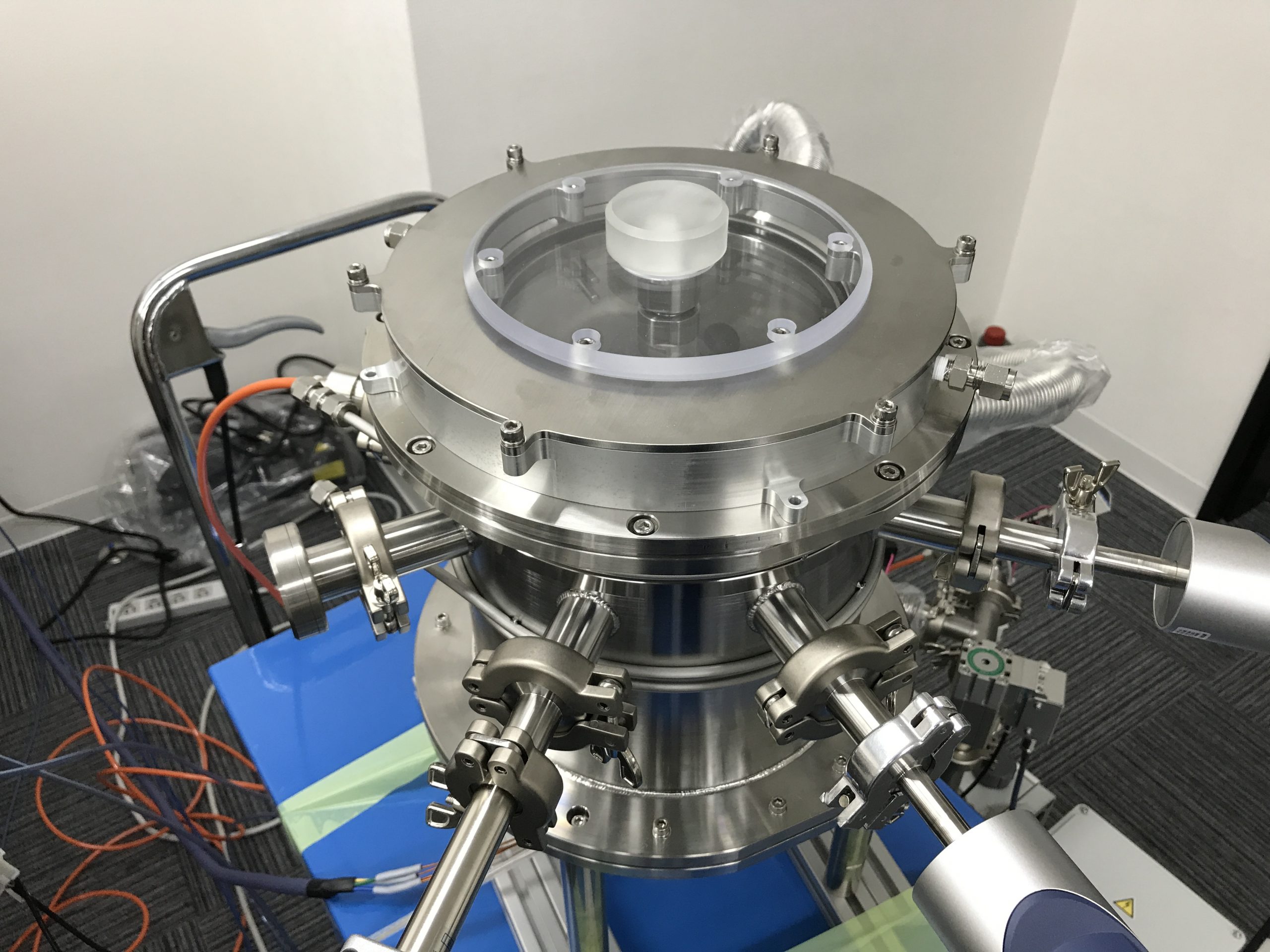

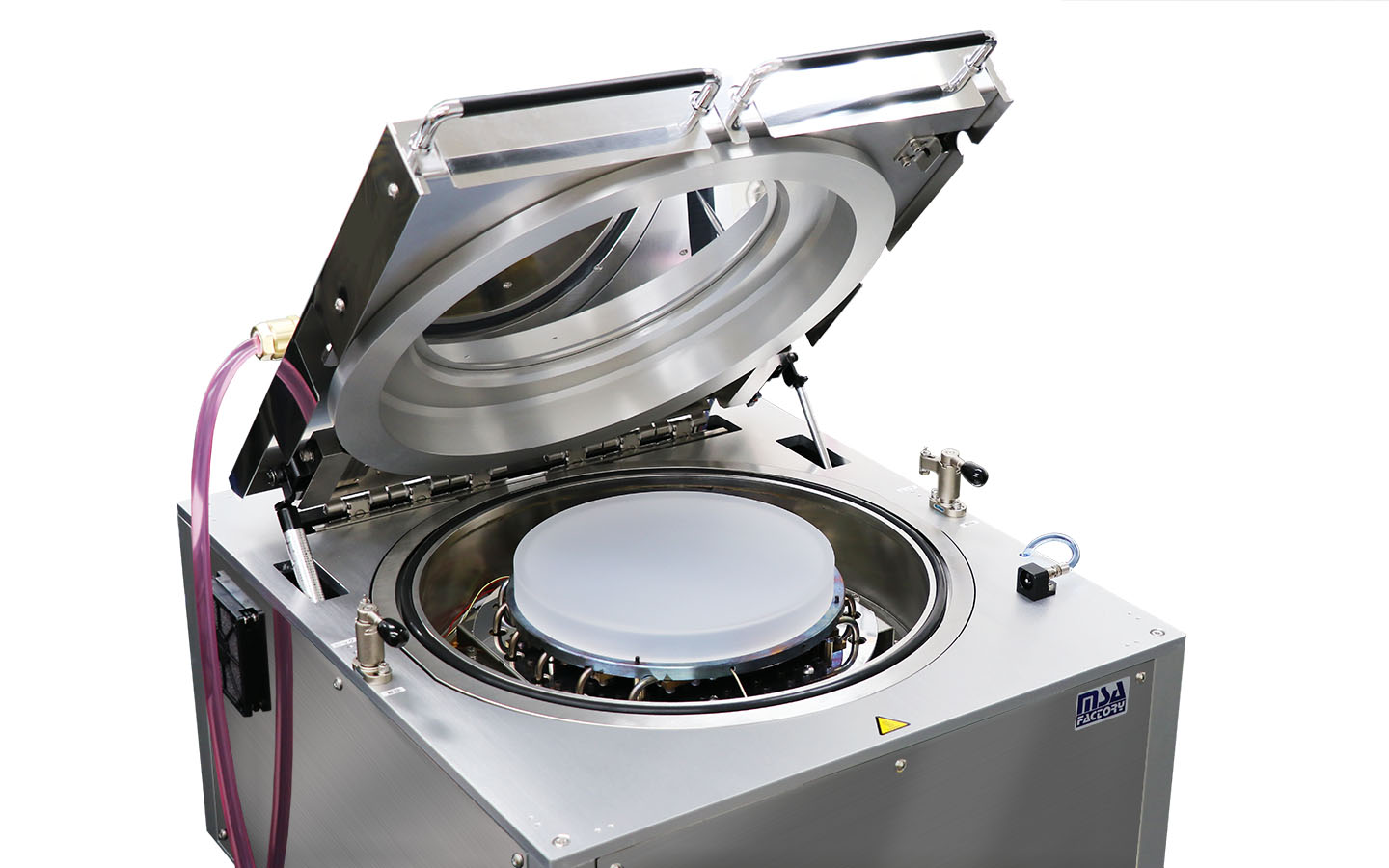

Custom-made vacuum hot plate chamber PH225 Maximum temperature up to 800℃

Main applications

It can be used as a vacuum heating laboratory tool, as well as a vacuum bake, vacuum drying furnace, and vacuum heating process development and evaluation device.

MSA FACTORY HEATING, VACUUM, MOTION CONTROL KNOW-HOW

Heating: Vacuum heating up to 800℃, Vacuum pressure control: Mass flow, valve conductance control, Motion control: Drive technology in a vacuum environment, etc. We have brought together various know-how.

Simple main unit + abundant options for a variety of applications

With special specifications, it can handle a maximum temperature of 800°C. It is also possible to incorporate the drive unit inside the tank.

The simple configuration allows you to build high temperature and vacuum processes. In addition, with a wide range of options and customization options, you can build the model that is best suited to your company.

high efficiency

Uniform heating is possible due to hot plate heating. Workpiece processing time is also short, and we invite you to compare the time with conventional processes.

safety

Optional safety functions such as overheating monitoring, earth leakage detection, and load disconnection can be added to the controller.

PH224_225_OP1 Option List

Quartz Bell Jar Option

List of models