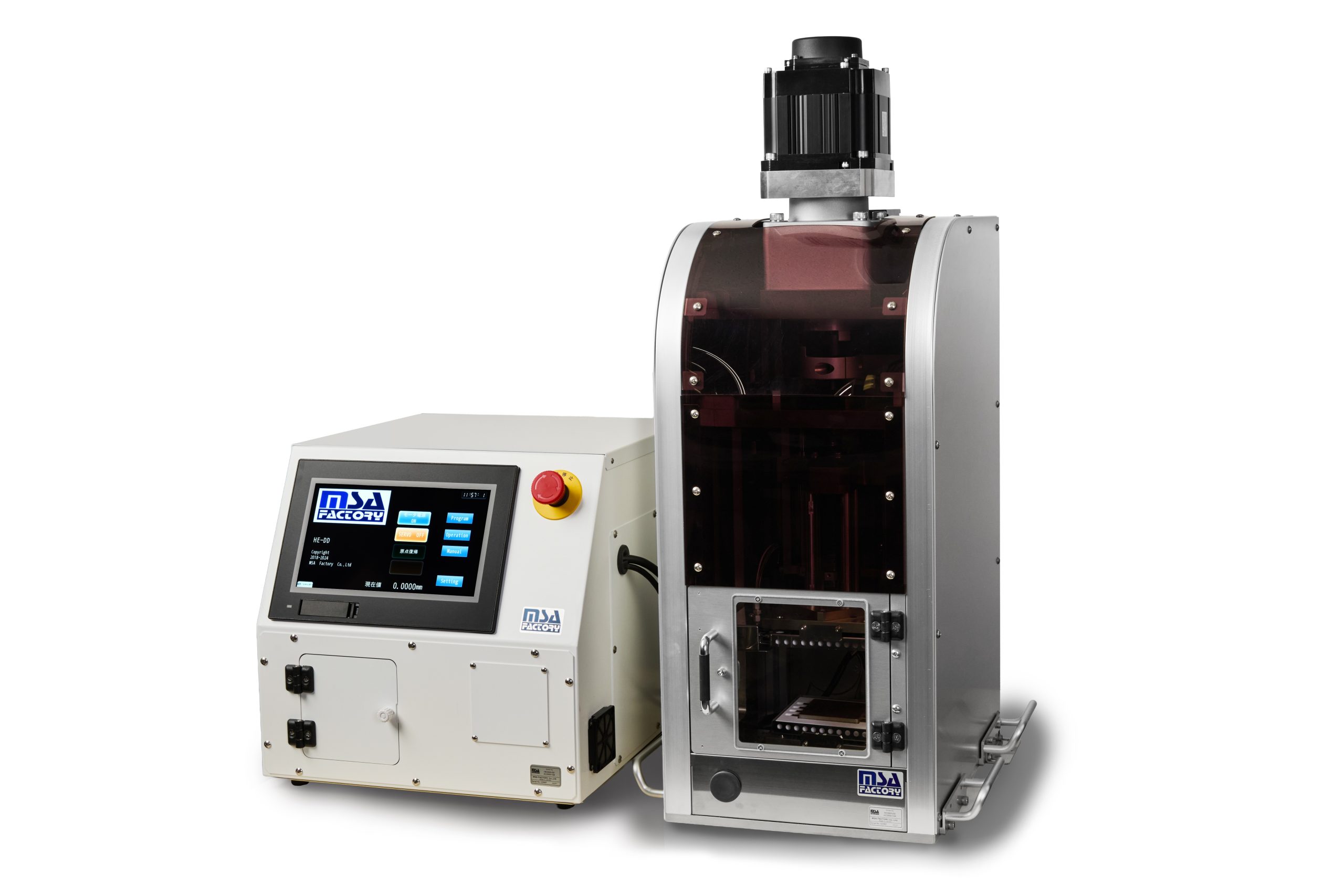

Ultra-high temperature hot presses, high-precision digital hot presses, servo presses

Ultra-high temperature hot presses, high-precision digital hot presses, servo presses

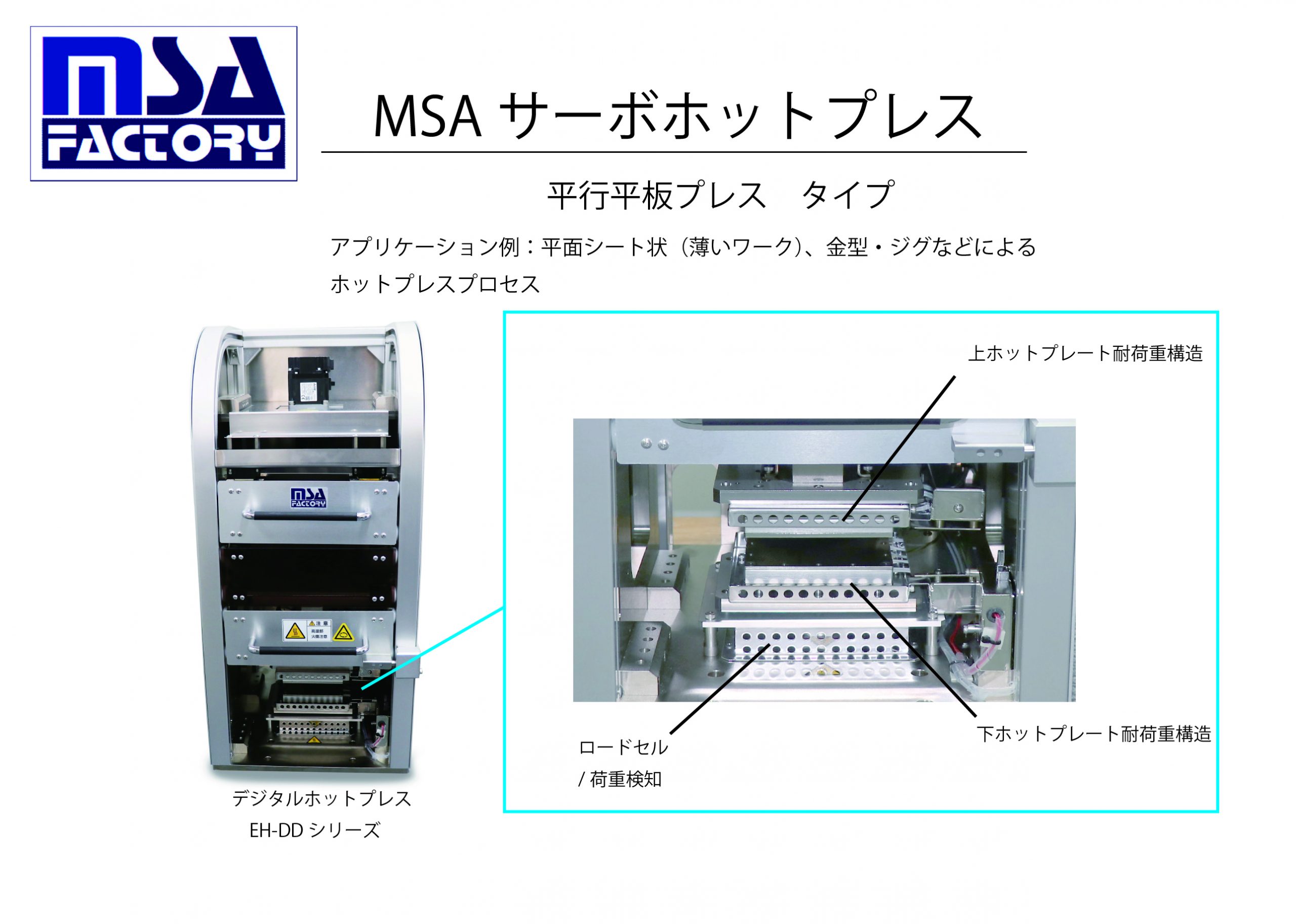

A wide variety of press configurations

Parallel flat plate type: Applications Load heating of flat workpieces (plate or film), load heating of molds, etc. Powder firing type: Firing and load heating on powder using molds, etc. Two main types of press structures are available.

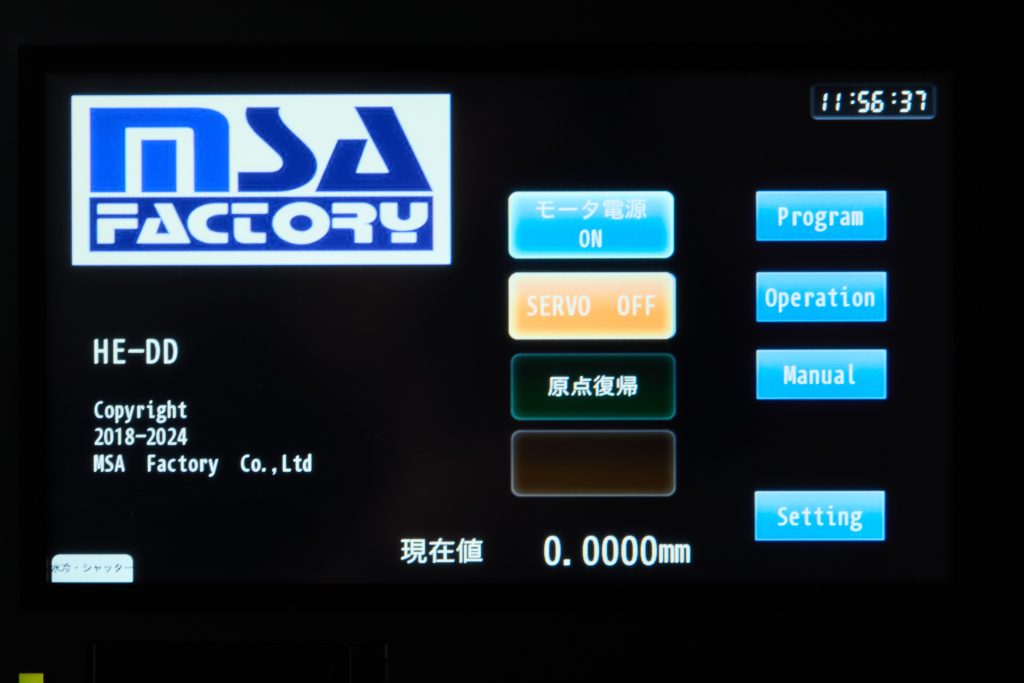

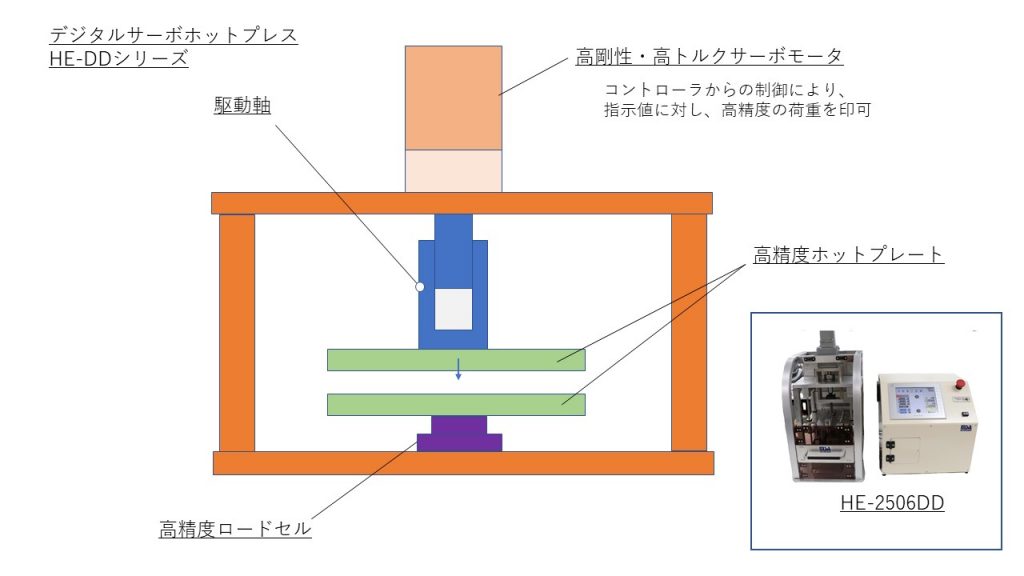

High performance and resolution

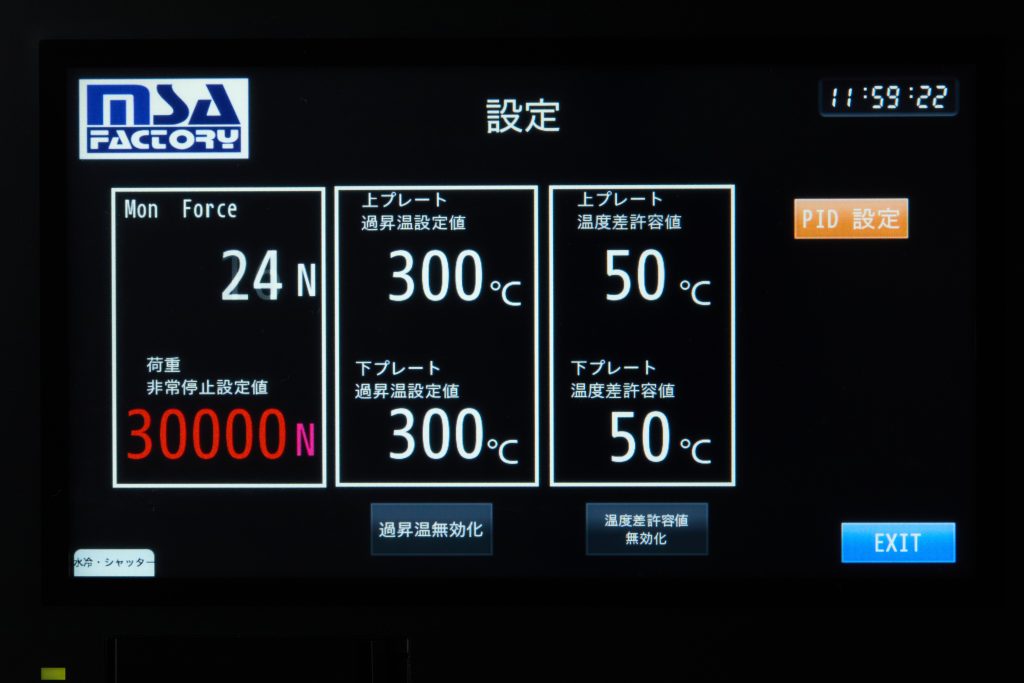

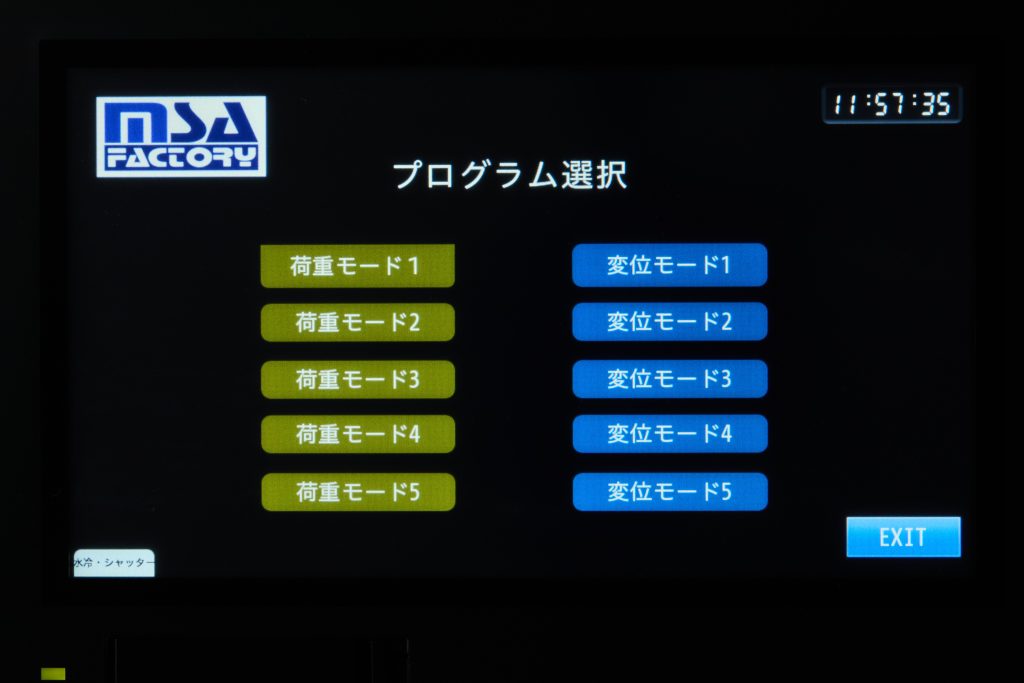

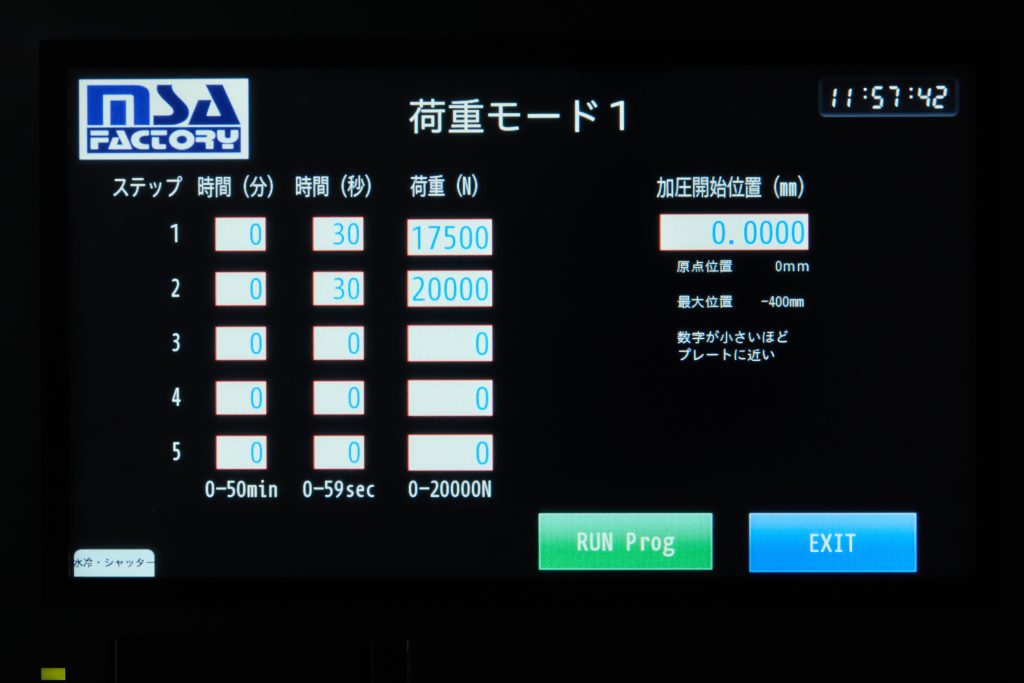

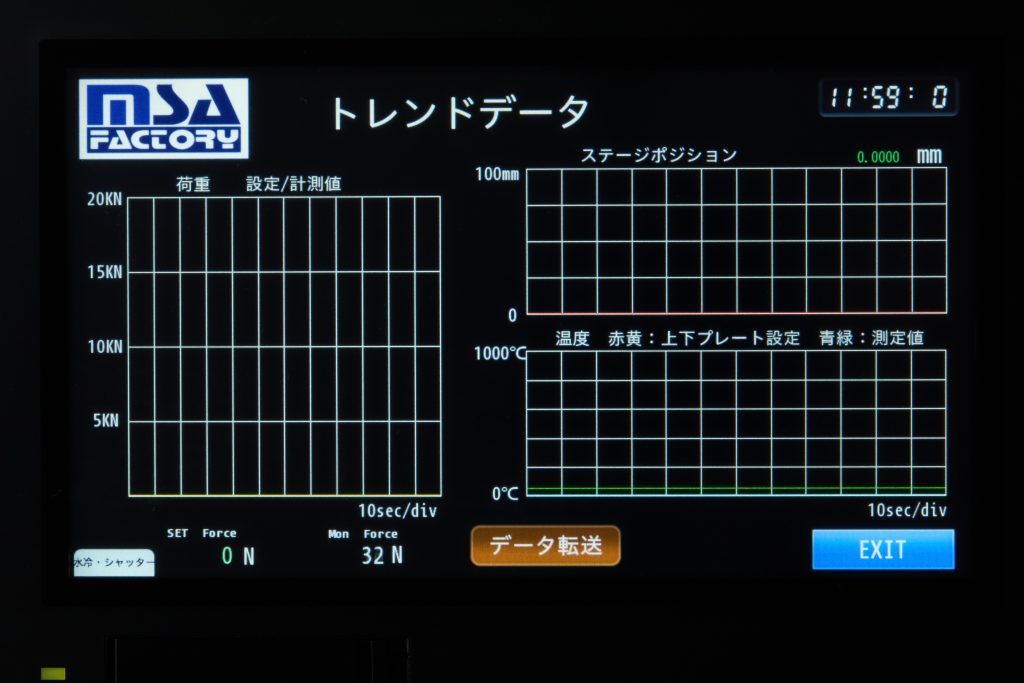

High-torque servo motors are controlled at high speed to realize a high-precision press process, digitally controlled to apply a constant load even when the workpiece is deformed, and with a maximum load resolution of 1N, fine load control is possible. (More detailed load control is possible depending on the maximum load.) Various hot presses can be supported, including load mode control and position (displacement) mode.

High temperature press

We support furnaces, molds, etc. up to ultra-high temperatures of 900°C, which was not possible with conventional methods, and also handle high-precision molds and surface treatment to prevent powder adhesion.

Plate heating surface

Lineup of maximum temperatures up to 900°C. Plate heating can be set to either one side (upper and lower plates) or both sides.

High temperature material testing and property analysis

Used for material testing and property analysis in contact with high temperatures. Optional features such as a thermal shutter are available to suppress the temperature rise of materials before testing.

Mold for powder molding

We also provide powder molding dies. We will make suggestions including materials and surface treatments.

Digital Servo Press VS Hydraulic Press Comparison

Digital Servo Press Advantages: (1) Highly accurate load (torque) adjustment function (2) Follows thermal deformation (also follows sample deformation during press process) (3) Semi-automates/automates press process (load/time, load/displacement, etc.) (4) Supports process in displacement mode (5) More safety features

Advantages of hydraulic presses: (1) Relatively inexpensive compared to servo presses (2) Easier to downsize and lower the head than with servo presses (3) Easier to handle high loads

Digital servo press Disadvantages: 1) More expensive (as a relative comparison to hydraulic)

Hydraulic press Disadvantages: 1) Fine load adjustment is difficult (due to manual adjustment)

safety

Safety features such as emergency stop function and safety shutter are standard equipment, and other options are available to improve safety. Please refer to the hot press general catalog .

Desktop installation

It can be installed on a table, saving space and eliminating the need for additional work such as foundation work. It can be operated from a 100V outlet. Depending on the load, an AC200V, φ3 power supply may be required.

Model list ① Temperature 600,400°C type

|

|

|

|

|

|---|---|---|---|---|

model number |

HE2006-DD |

HE2004-DD |

HE4006-DD |

HE4004-DD |

Max. temperature |

600℃ | 400℃ | 600℃ | 400℃ |

Press Thrust |

20KN | 40KN | ||

Plate Material |

heat-resistant superalloy | |||

Plate surface size |

Top and bottom Heat plate size □80mm | |||

Supply voltage |

AC200V, SINGLE PHASE OR THREE PHASE | AC200V, 3 PHASE | ||

controller |

PCE200, TOUCH PANEL CONTROLLER | |||

Load Monitor |

High-precision load cell/analog-to-digital conversion | |||

control function |

Force/time mode (setting in 1N units), displacement/time mode (setting in 1μm units), number of recipes 5 each | |||

Standard safety features |

Door lock function when servo is turned on, door lock function according to set temperature, earth leakage breaker, over-temperature monitoring function (double sensor), abnormal stop function when overload, emergency stop button (one on controller panel), safety cover (all sides) | |||

option |

Sample temperature measurement sensor, workpiece thermal shutter, air and water cooling functions | |||

Press section structure |

-P (PARALLEL PLATE), -H (FURNACE TYPE) | |||

Product size |

W330mm×D350mm×H770mm Please refer to the specification diagram for details. | |||

Model List ② Temperature 800,900°C type

|

|

|

|

|

|---|---|---|---|---|

model number |

HE2008-DD |

HE2009-DD |

HE4008-DD |

HE4009-DD |

Max. temperature |

800℃ | 900℃ | 800℃ | 900℃ |

Press Thrust |

20KN | 40KN | ||

Plate Material |

heat-resistant superalloy | |||

Plate surface size |

Top and bottom Heat plate size □80mm | |||

Supply voltage |

AC200V, SINGLE PHASE OR THREE PHASE | AC200V, 3 PHASE | ||

controller |

PCE200, TOUCH PANEL CONTROLLER | |||

Load Monitor |

High-precision load cell/analog-to-digital conversion | |||

control function |

Force/time mode (setting in 1N units), displacement/time mode (setting in 1μm units), number of recipes 5 each | |||

Standard safety features |

Door lock function when servo is turned on, door lock function according to set temperature, earth leakage breaker, over-temperature monitoring function (double sensor), abnormal stop function when overload, emergency stop button (one on controller panel), safety cover (all sides) | |||

option |

Sample temperature measurement sensor, workpiece thermal shutter, air and water cooling functions | |||

Press section structure |

-P (PARALLEL PLATE), -H (FURNACE TYPE) | |||

Product size |

W330mm×D350mm×H770mm Please refer to the specification diagram for details. | |||