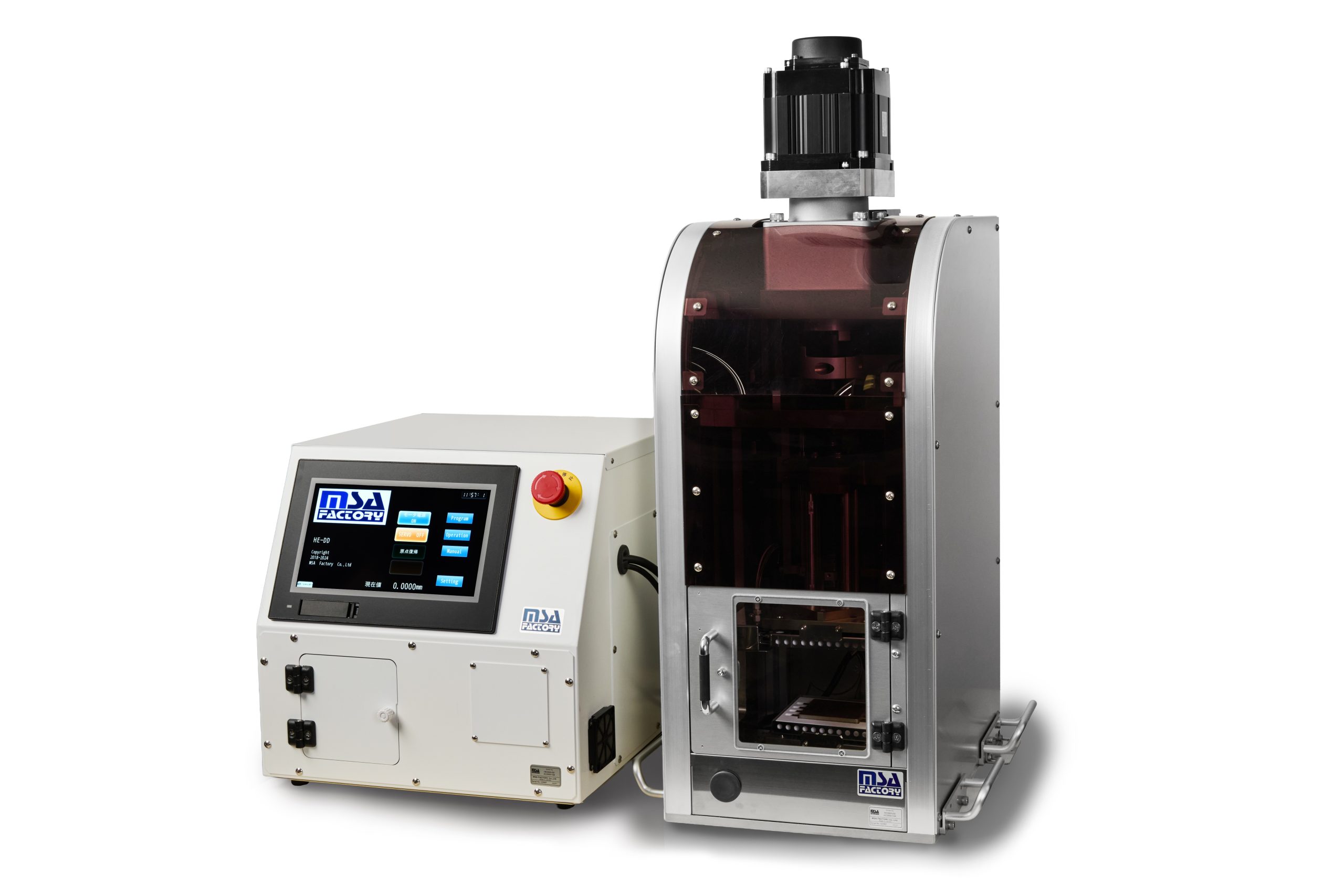

We have insulation evaluation equipment that can handle up to ultra-high temperatures, high-precision digital hot presses, servo presses, and high safety features that reliably exhaust odors, smoke, and other substances.

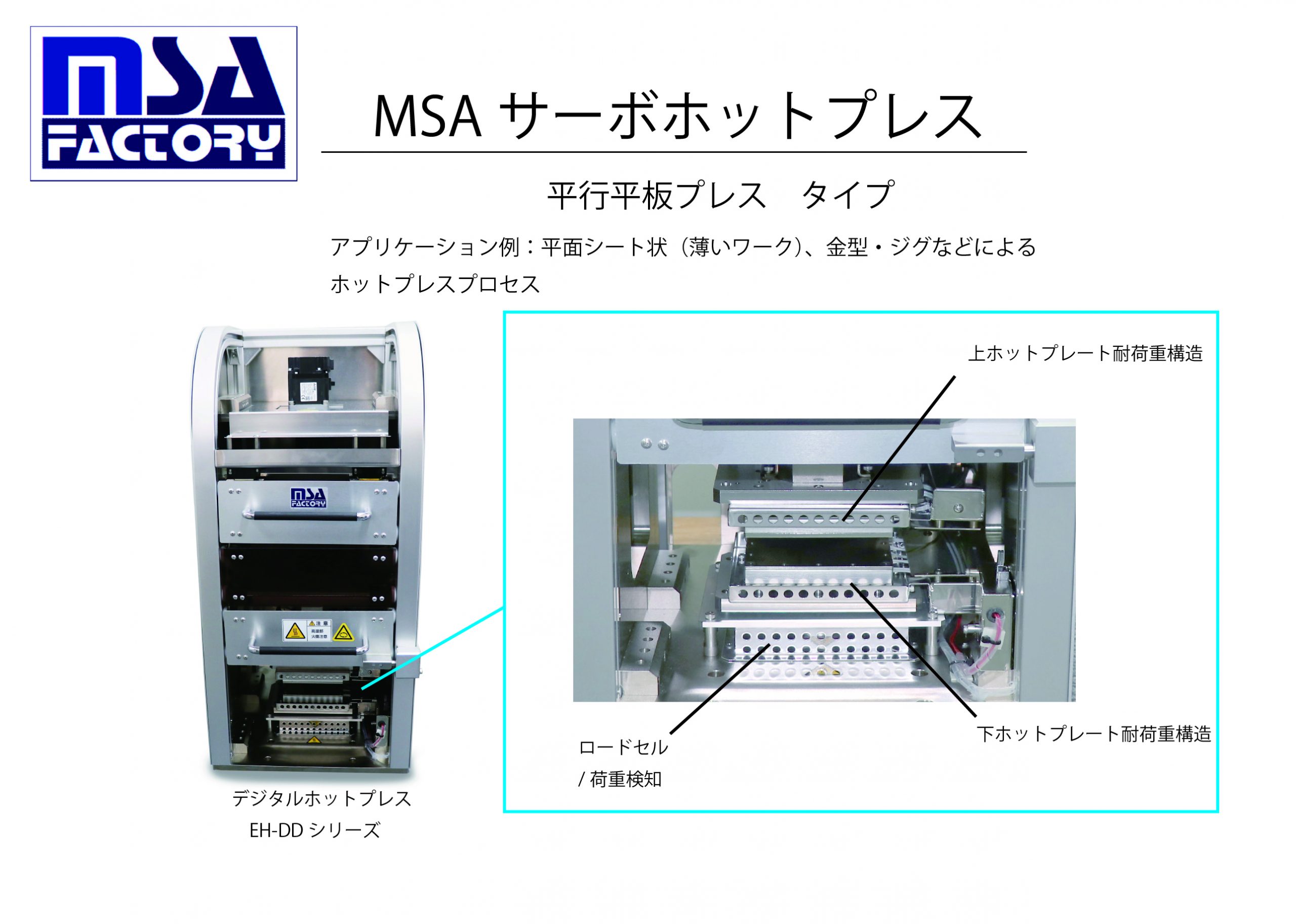

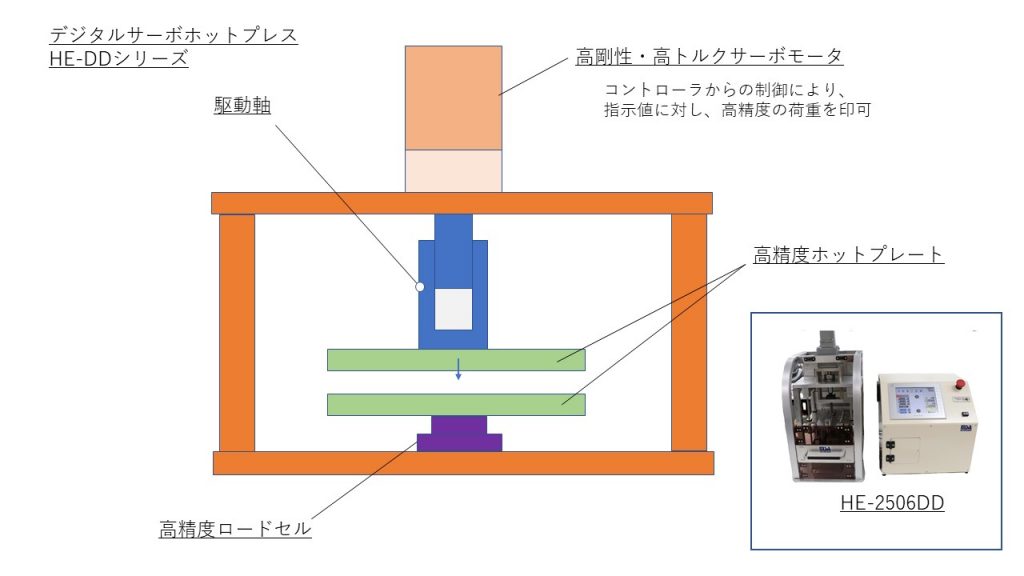

High performance and resolution

HIGH-TORQUE SERVO MOTOR IS CONTROLLED AT HIGH SPEED TO REALIZE HIGH-PRECISION PRESS PROCESS, DIGITALLY CONTROLLED TO APPLY CONSTANT LOAD EVEN IF WORKPIECE IS DEFORMED, AND LOAD RESOLUTION UP TO 1 N FOR FINE LOAD CONTROL. (MORE DETAILED LOAD CONTROL IS POSSIBLE DEPENDING ON THE MAXIMUM LOAD.)

Load mode control, position (displacement) mode, etc., can be applied to a variety of materials.

Heat Flux Sensors

A heat flux meter is provided. Data can be stored in the controller or taken out from the take-out terminal block to a data logger. A data logger can also be attached (optional).

High-temperature press, individual temperature control of upper and lower heat plates

Individual temperature control can be set in 1°C increments up to the previously unsupported ultra-high temperature of 900°C.

Plate heating surface

Maximum temperature 900°C lineup. Plate heating can be set for either one side (upper or lower plate) or both sides. Water-cooling of the lower heating plate to constant temperature (excluding influence from the upper heating plate) is also available as an option.

High temperature material testing and property analysis

Used for material testing and property analysis in contact with high temperatures. Optional features such as a thermal shutter are available to suppress the temperature rise of materials before testing.

test procedure

Configurations are available for the protective heat plate method (GHP method) and the heat flow meter method (HFM method).

safety

The heat plate, motor, and other parts are enclosed by a safety cover. Smoke exhaust can be removed by ducting, so there is little unpleasant odor leaking into the room. When the motor servo is on (in preparation for motor operation) or the heating plate is hot (variable temperature setting), the door cannot be opened or closed due to the door lock. Also, the motor servo is not turned on when the door is open.

Desktop installation

It can be installed on a table, saving space and eliminating the need for additional work such as foundation work. It can be operated from a 100V outlet. Depending on the load, an AC200V, φ3 power supply may be required.

List of models

|

|

|

|

|

|---|---|---|---|---|

model number |

HE2006-DD |

HE2004-DD |

HE4006-DD |

HE4004-DD |

Max. temperature |

800℃ | 900℃ | 800℃ | 900℃ |

Plate size *Customization is possible except for those listed on the right. |

70×70mm | 125×125mm | ||

Plate Material |

heat-resistant superalloy | |||

Press Thrust |

20KN | |||

Supply voltage |

AC200V, SINGLE PHASE OR THREE PHASE | |||

controller |

PCE200, TOUCH PANEL CONTROLLER | |||

Standard equipment and features |

Heat flux meter, velocity meter voltage output, thermometer output, waste heat fan | |||

option |

Thermal shutters, automatic sample transfer, additional temperature sensor (with connector), additional heat flux meter, waste heat and exhaust duct flange (for odor, smoke, dust, etc.), lower heat plate water cooling and chiller, data logger for heat flux meter and thermometer | |||

Product size |

W330mm×D350mm×H770mm Please refer to the specification diagram for details. | |||