MSA FACTORY MACHINED PARTS OUTSOURCING BUSINESS

Procurement support role

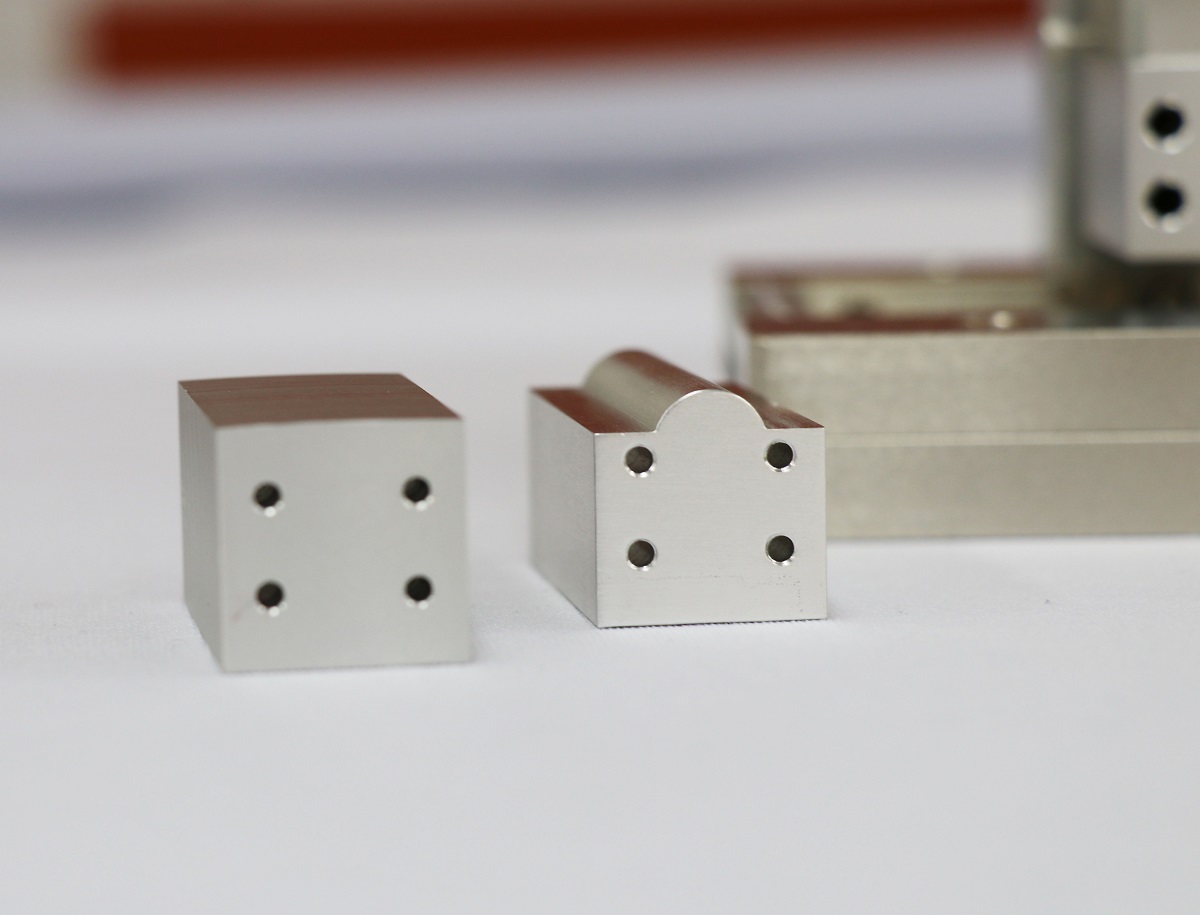

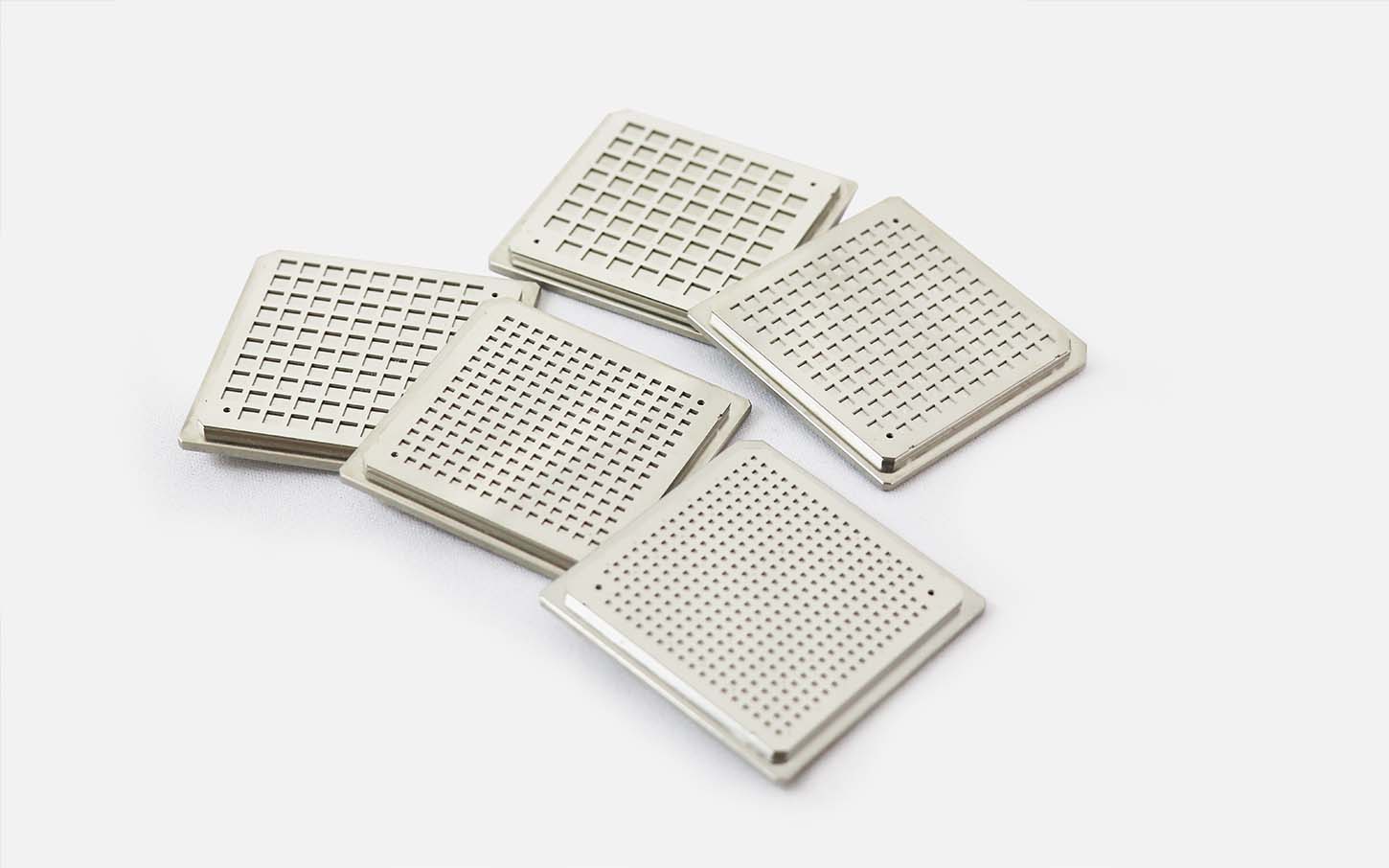

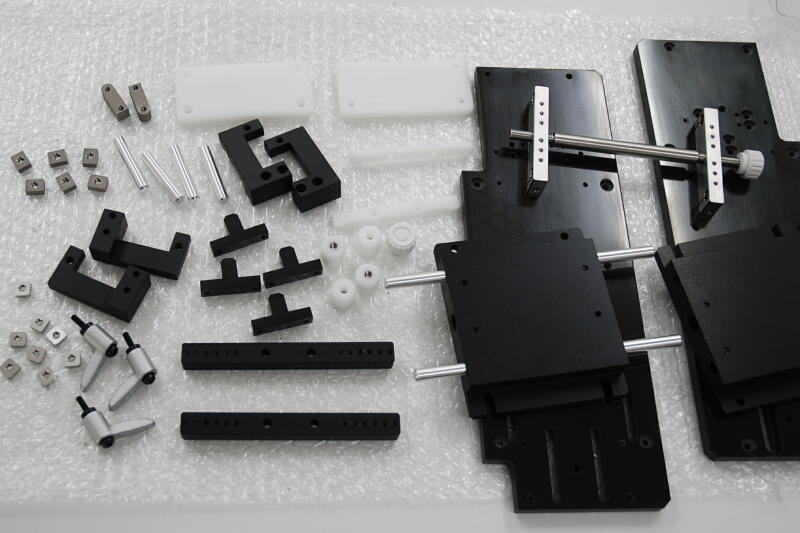

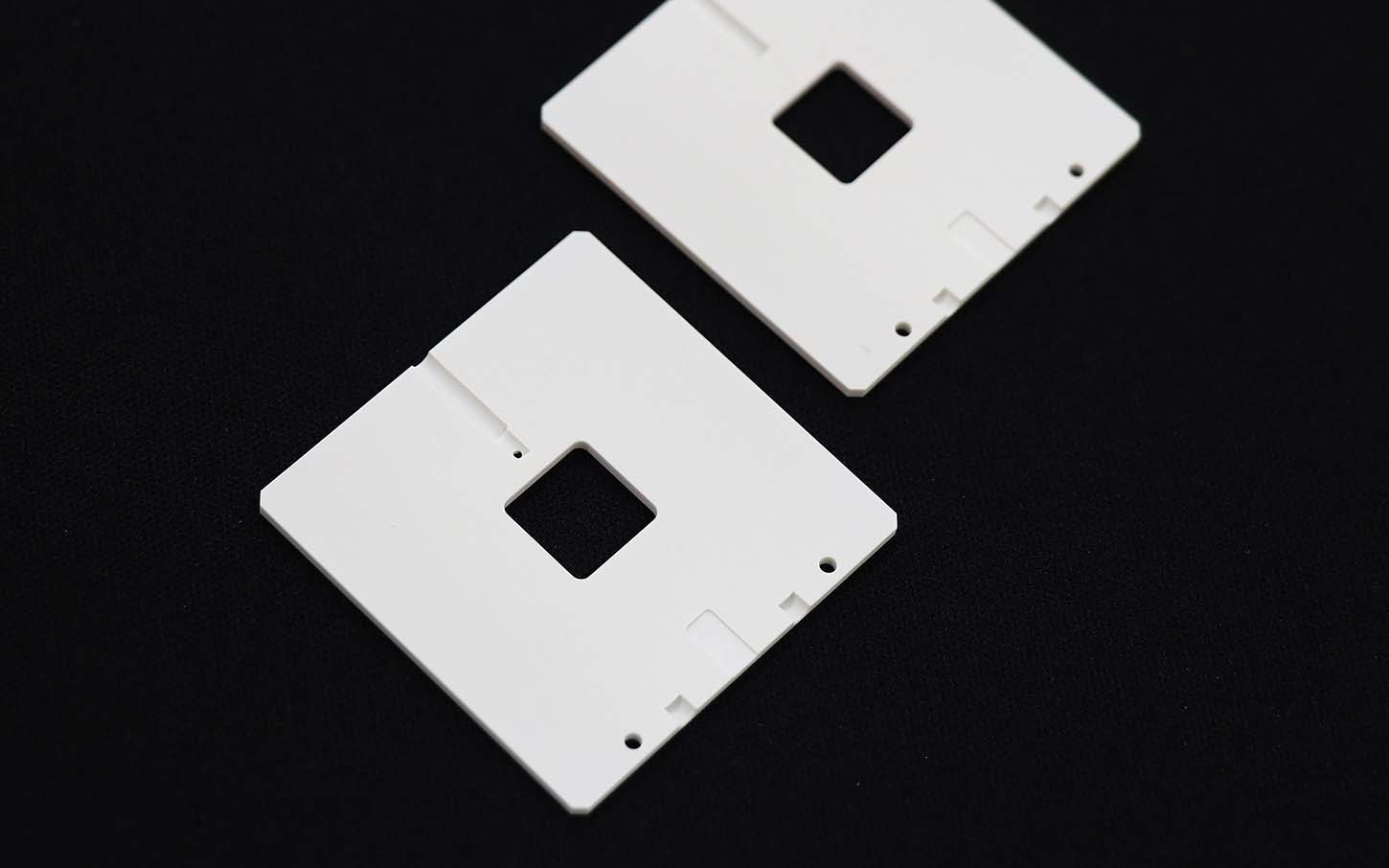

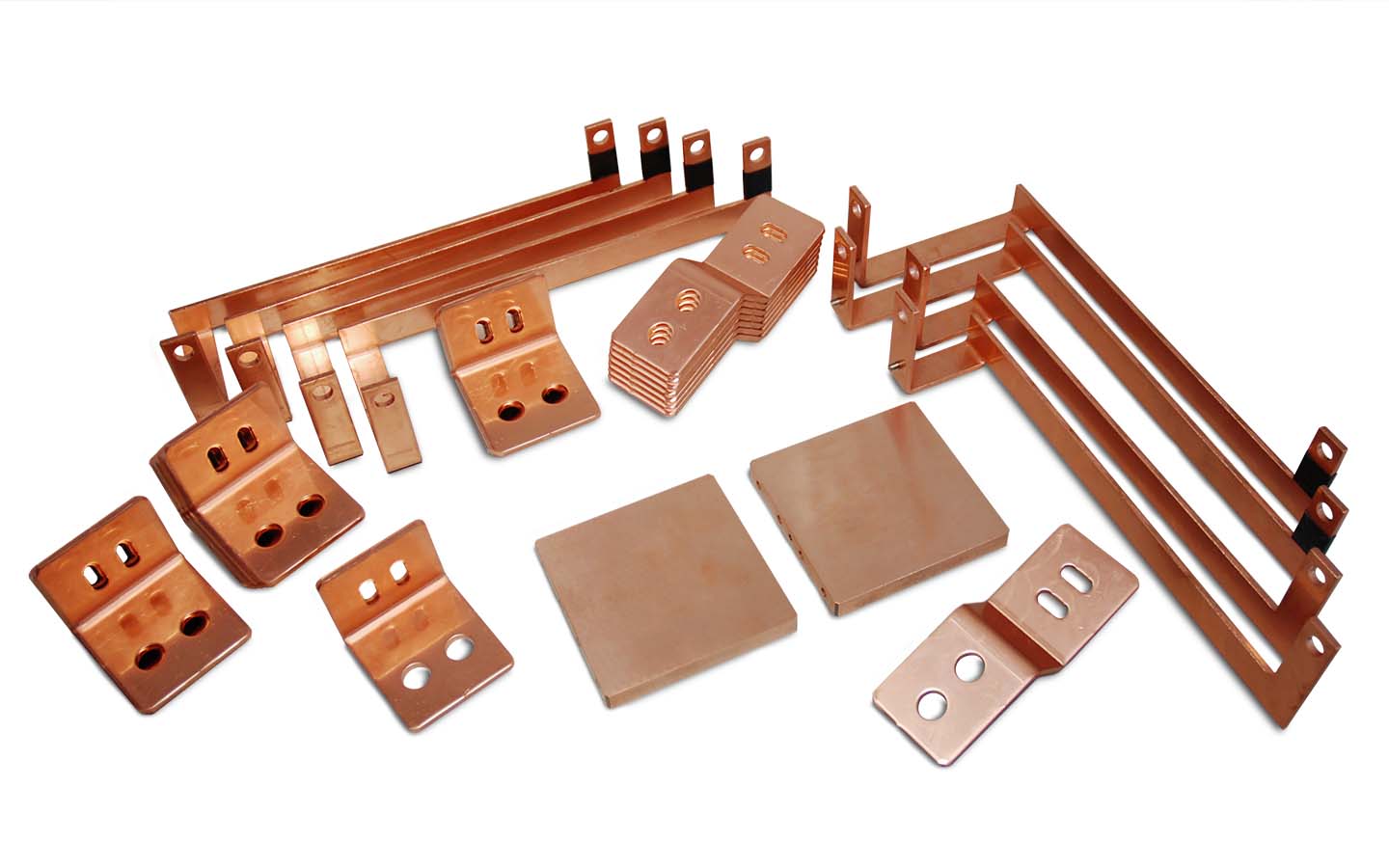

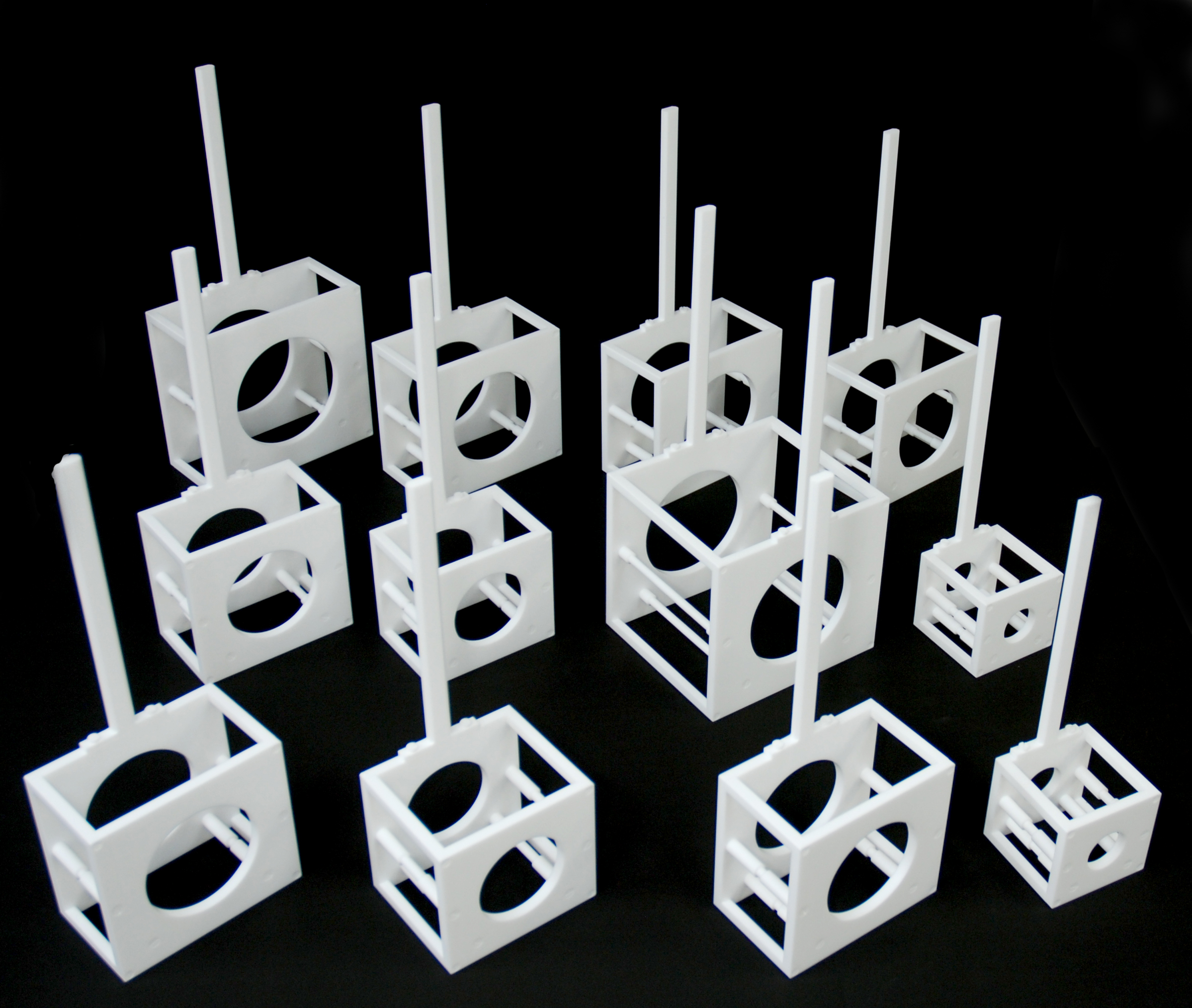

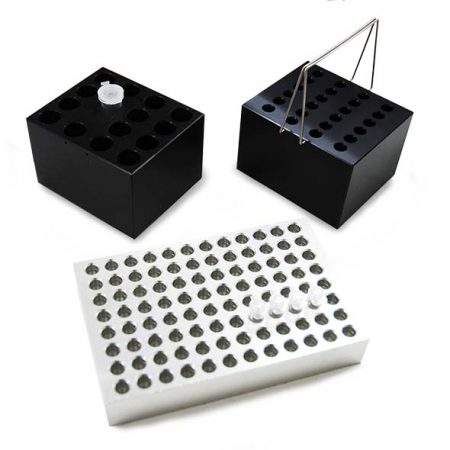

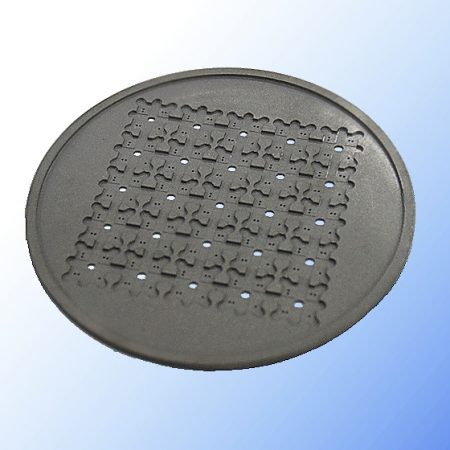

MSA Factory provides precision machining for R&D and test equipment using machining, milling, and turning centers. We can handle a wide variety of materials including aluminum, copper, stainless steel, and PTFE, and can perform high-precision machining in increments of ±0.01 mm. We can handle everything from a single prototype to small-lot production with short delivery times, helping to speed up equipment development.

VARIOUS PARTS ARE NEEDED AT EACH WORKPLACE AND SITE. IT IS DIFFICULT FOR A SINGLE COMPANY TO PROCURE PARTS, AND MANY OF THEM HAVE TO GO THROUGH MULTIPLE PROCESSES AND SUPPLIERS. MSA FACTORY WAS FOUNDED TO SUPPORT THIS.

We will provide a quotation if you submit a processing drawing.

Flow of delivery ①Receipt of drawings → ②Submission of quotation from our company → ③Order from your company → ④Delivery

Please click here to request a quote.

Trends in the sophistication of mechanical processes

With the evolution of processing machines, accuracy is increasing and the number of options is increasing every day. We aim to meet our customers' cost performance improvement needs by considering appropriate machining processes.

Material procurement, surface treatment

In order to ensure the functionality of parts, pre- and post-processing, material procurement, surface treatment and processing are important. We are improving our operations so that we can support all of these.

-

The company specializes in precision machining, small lot production, prototype processing, and R&D parts.

-

We specialize in machining, milling, turning, high-precision machining (±0.01mm, etc.), aluminum / copper / resin processing, and parts for testing equipment.