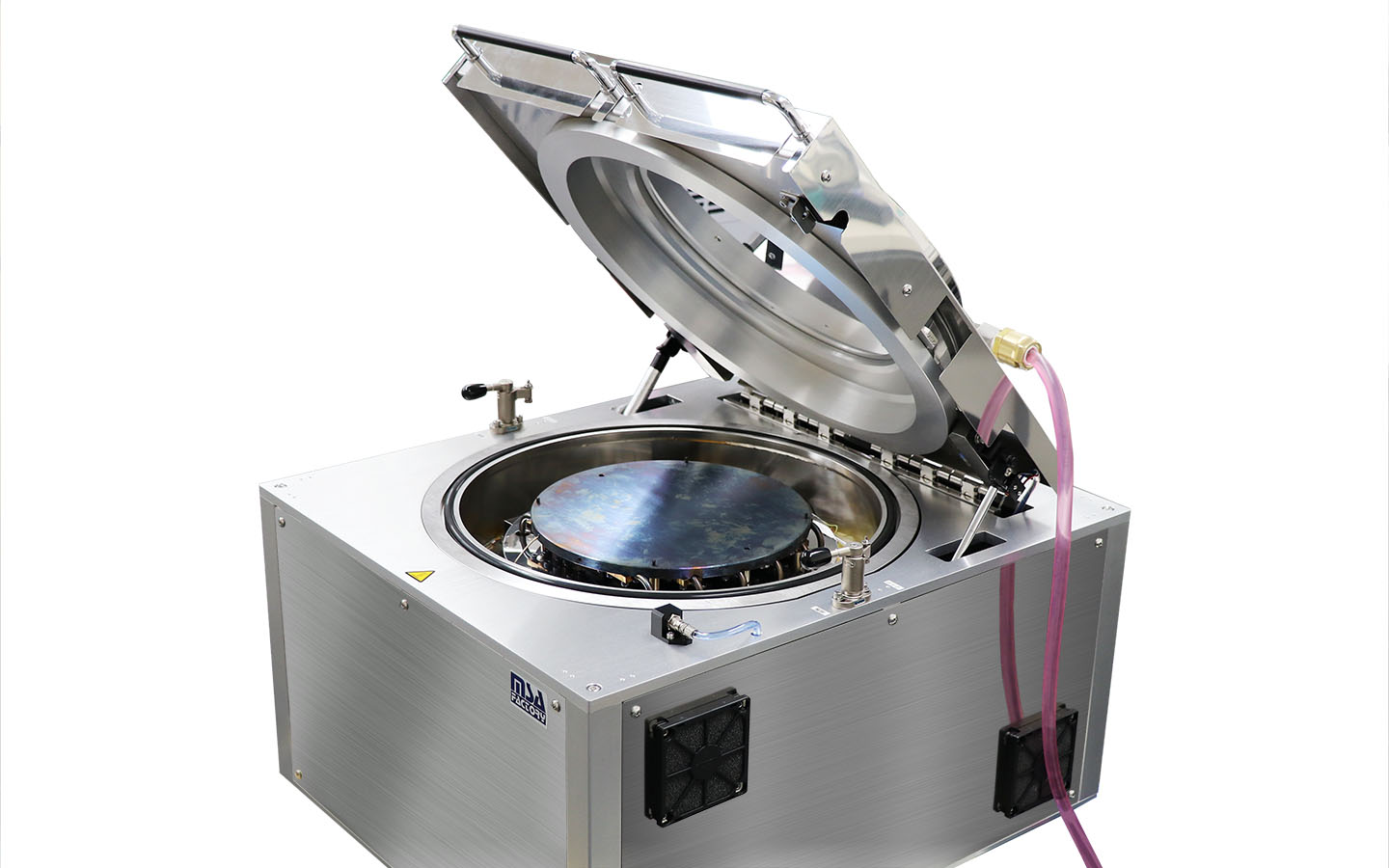

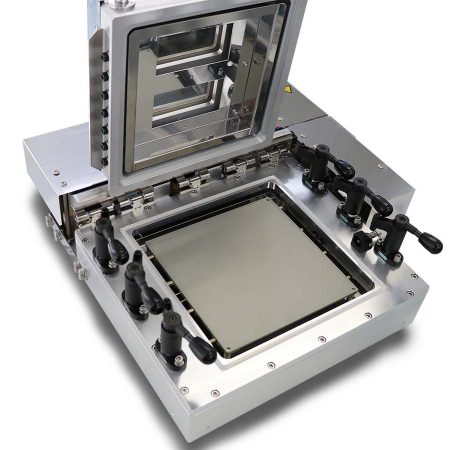

Vacuum heating and drying furnace Chamber PH225 Max. temperature 800°C

More precise and efficient drying and baking processes in a vacuum environment. The MSA FACTORY PH225 Series offers a wide range of custom-designed options, including a vacuum furnace capable of heating up to 800°C. The PH225 Series optimizes heating uniformity and temperature rise rate for each workpiece, significantly reducing experiment time during the prototyping and evaluation stages.

Color touch panel for intuitive operation

Safety-oriented design including over-temperature monitoring and emergency stop

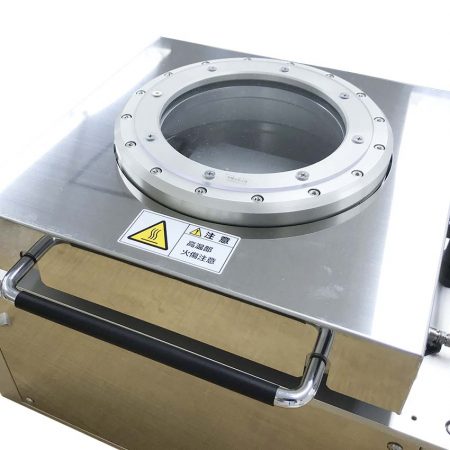

Observation window to check workpiece status in process in real time

High reliability with environmental control options including oxygen concentration and dew point meters and vacuum pressure control

Ideal equipment for laboratories and prototype labs. You can trust us to process heat-sensitive materials and materials that do not like oxidation.

Main applications

Vacuum Heating Processes The PCC118-HVMJ can be used as a vacuum baker, vacuum dryer, or VCD. The color touch panel temperature controller / PCC118-HVMJ enables easy operation of the vacuum heating process.

MSA FACTORY HEATING KNOW-HOW

We combine various know-how such as heater design, thermal insulation, and thermal radiation. The software is also highly functional.

Simple main unit + abundant options for a variety of applications

A simple main unit and controller enable the construction of high-temperature and vacuum processes. A wide variety of options and customization options allow you to build a model that is best suited for your company.

Main options/all customizable

Workpiece support: proximity pins, positioning pins, lifter function

Gas flow: O2, H2 (mixed gas), others (N2 gas is standard specification)

Measurement function: O2 concentration system, dew point meter, and Pirani vacuum gauge are standard specifications

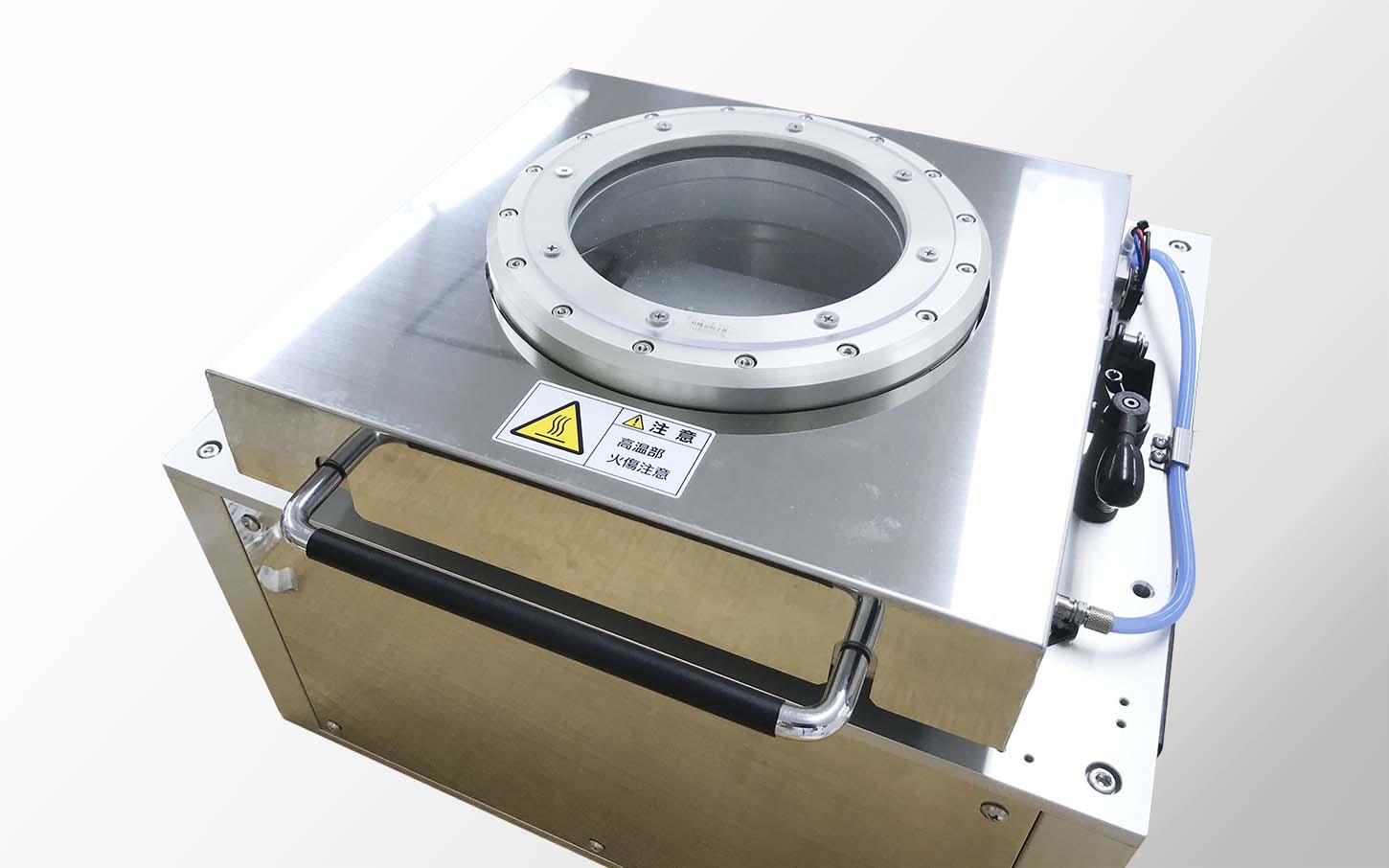

Observation window: Heat-resistant glass, quartz glass (wide aperture type is available only with quartz glass)

Long time and high temperature operation: Water cooling unit

For volatile materials: Cooling trap unit, Vacuum flexible tube heater added

Pressure and flow control: Mass flow control, conductance valve vacuum pressure control, slow exhaust, slow bend

Workpiece transfer: Wafer transfer unit

Sub-chamber: Load lock type wafer transfer unit

Option list is here PH224_225_OP1 *Please contact us for other options.

PH225 catalog is here PH225 catalog (English version PH225_EN)

high efficiency

Uniform heating is possible because of hot plate heating. The workpiece processing time is shorter than any other vacuum dryer, and we invite you to compare the time required with conventional processes.

Long-time heating/ultra-high temperature vacuum heating

Supports heating processes exceeding one hour and ultra-high temperatures (800°C). To support long-term workpieces, a water-cooling function (optional), chiller and circulating cooling water are required separately.

safety

The controller is equipped with safety functions that include an over-temperature monitoring function, an emergency stop function, a leakage current detection function, and a load disconnection function.

Model list①

Model list②