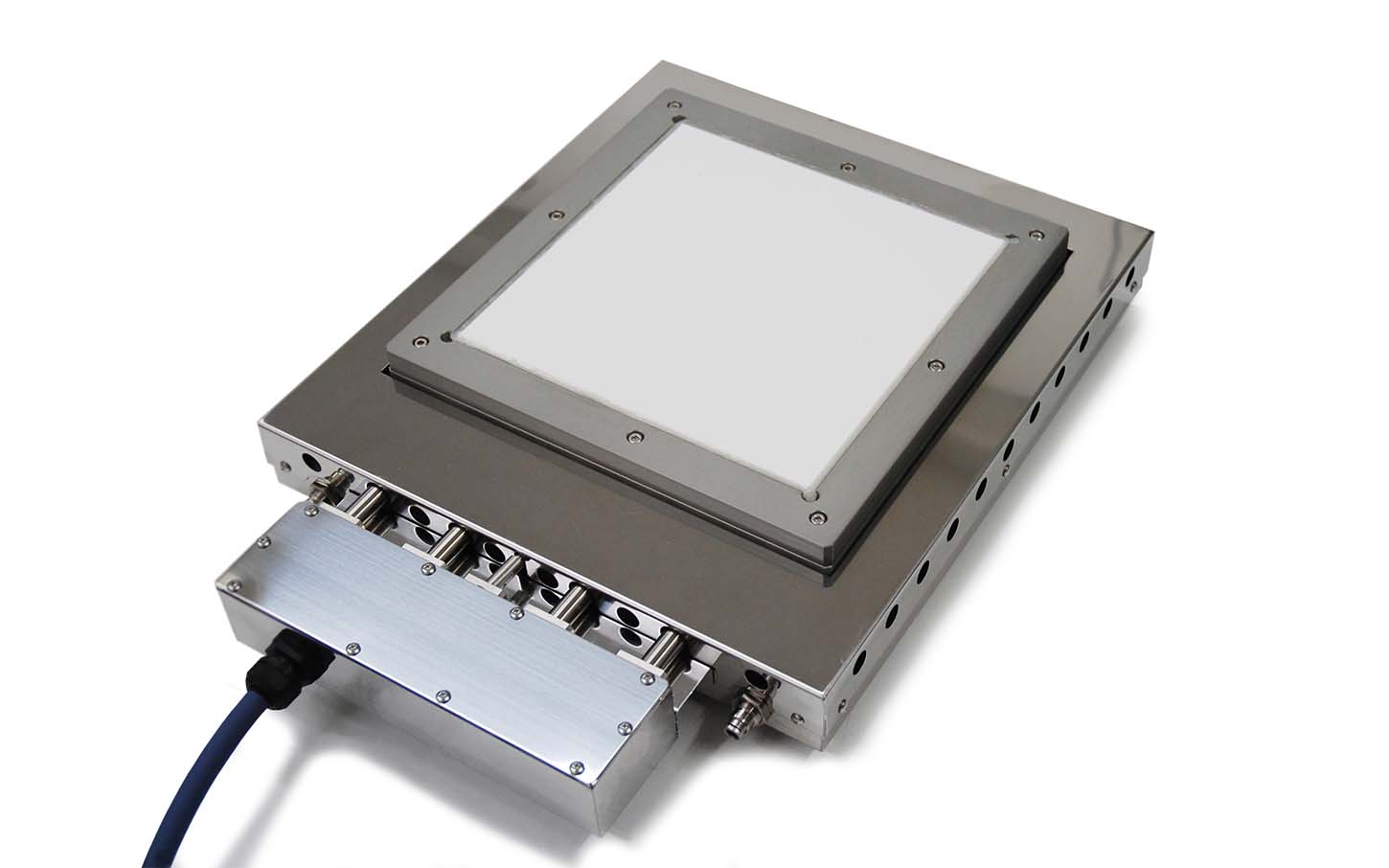

Thin type, Adsorption stage Adsorption plate

Adsorption Stage/Plate

Adsorption method

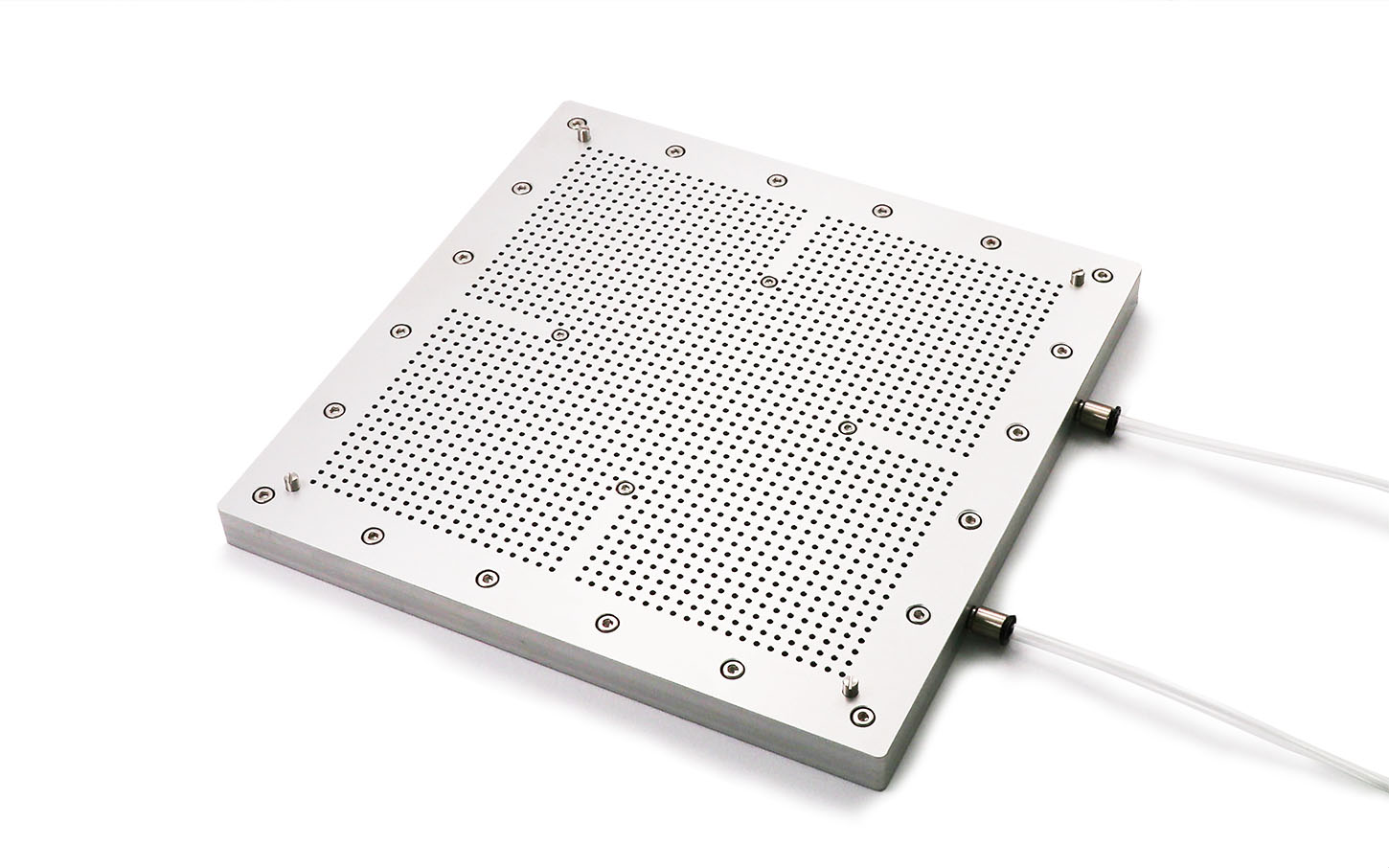

Through-hole: Suction holes are placed at the suction points, and the negative pressure of the vacuum pump is used to suction the workpiece. This is the most powerful suction method.

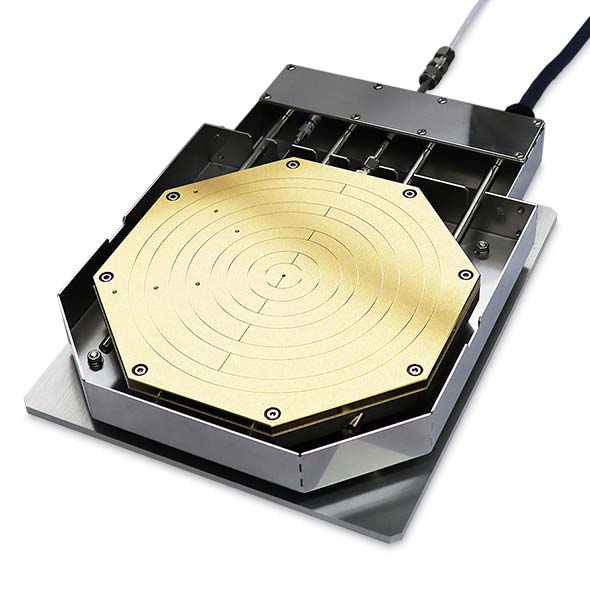

V-shaped hole: From the center through-hole, a single stroke V-shaped hole can be negatively pressurized to enable suction independent of the workpiece size. This is a suitable chucking method when multiple workpiece sizes need to be handled.

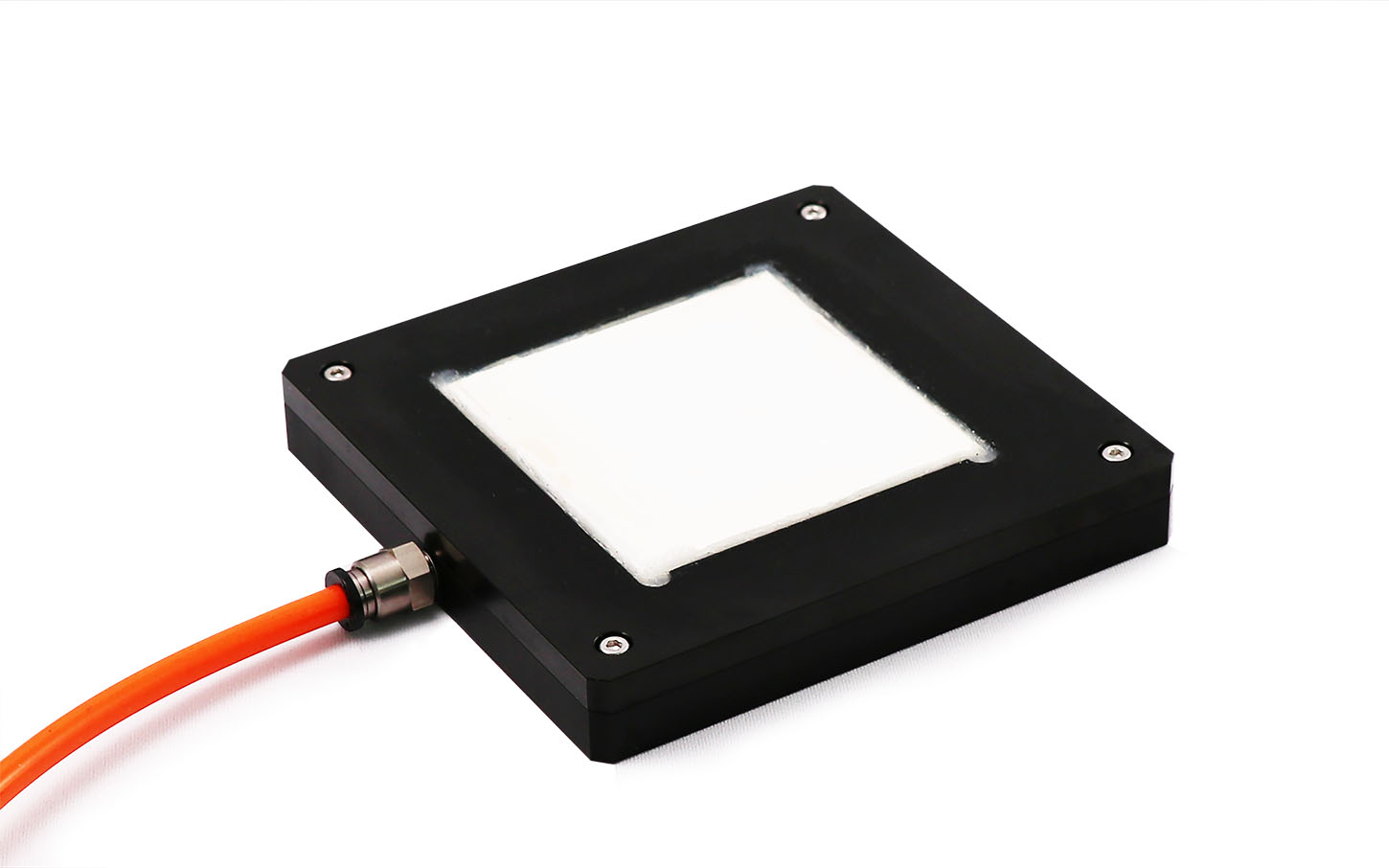

Porous ceramic: If the workpiece is extremely thin (e.g., glass, film-like, with a slot, hole, etc.), this chucking method does not cause deformation to the workpiece.

For through-hole and porous ceramic adsorption, the workpiece size and stage size (adsorption area size) must be matched.

Heat-resistant specifications and compatibility

Heat-resistant construction developed with hot chucks is also available. Heat-resistant specifications up to 200°C standard and 500°C by special order are also available. The maximum temperature varies depending on the size and suction method.

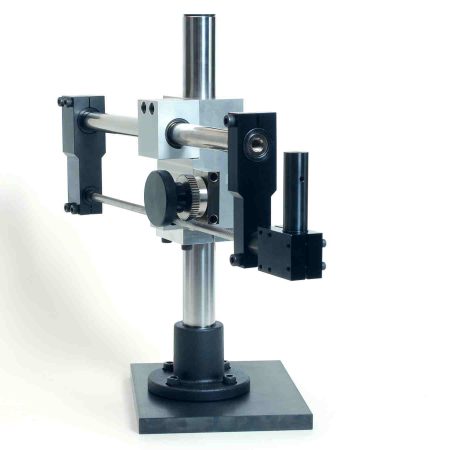

Custom Shape

Customized holes for positioning pins, holes for fixing to other stages, etc. are available.

Controller for vacuum suction

A suction controller is also provided. The controller controls suction ON/OFF, suction pressure, vacuum pump ON/OFF, ejector, and other operations at hand.

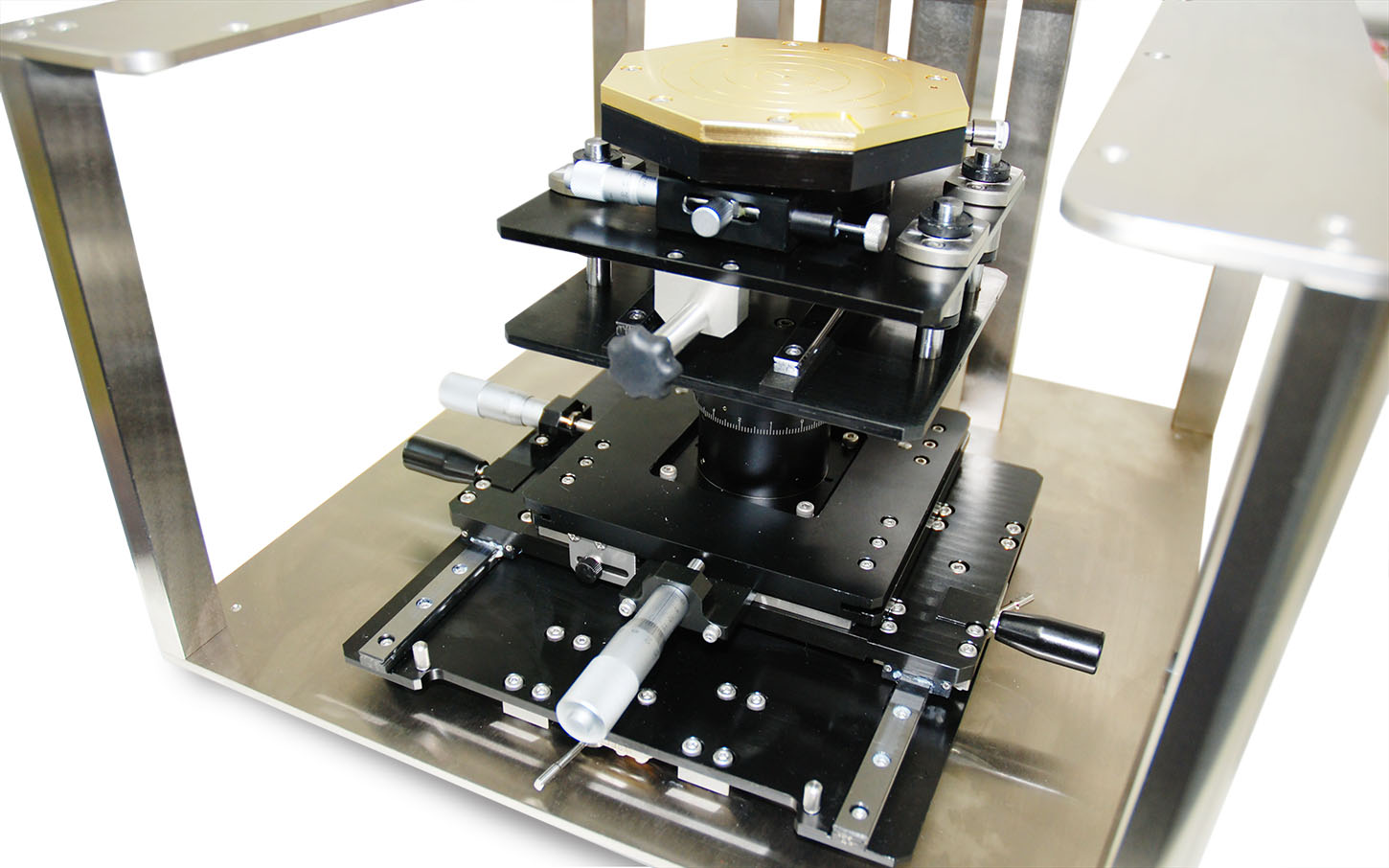

MULTI-AXIS CONFIGURATION MSA-MULTI-STAGE

MSA MULTI-STAGE (MULTI-AXIS CUSTOMIZED) STAGES COMBINED WITH OTHER AXIS-DRIVEN STAGES, WE CAN PREPARE A STAGE TO SUIT YOUR APPLICATION.

Through system Chuck/positioning pins are customizable THV-T200 Custom

Porous ceramic chuck 100 x 100mm size THV-C100

Related products Porous hot chuck / up to 200℃ Here

Related product PH201K-06 Gold plated surface treatment specification, max. temperature 200℃ Click here

Model list ① THV series suction surface square type (workpiece suction/chuck stage)

model number |

THV-T |

THV-V |

THV-C |

|---|---|---|---|

Stage size 100 x 100 mm |

THV-T100 | THV-V100 | THV-C100 |

Stage size 125 x 125 mm |

THV-T125 | THV-V125 | THV-C125 |

New! Stage size 150 x 150 mm |

THV-T150 | THV-V150 | THV-C150 |

New! Stage size 175 x 175 mm |

THV-T175 | THV-V175 | THV-C175 |

New! Stage size 200 x 200 mm |

THV-T200 | THV-V200 | THV-C200 |

Adsorption method |

Through-hole adsorption | V-groove adsorption | Porous ceramics |

Recommended vacuum pump |

Dry pumps, vacuum ejectors | ||

Model List (2) THV Series: Suction surface type 0 (Workpiece suction/chuck stage)

model number |

THV-T-D |

THV-V-D |

THV-C-D |

|---|---|---|---|

New! Stage size φ100mm |

THV-T100-D | THV-V100-D | THV-C100-D |

New! Stage size φ125mm |

THV-T125-D | THV-V125-D | THV-C125-D |

New! Stage rhino φ150mm |

THV-T150-D | THV-V150-D | THV-C150-D |

New! Stage size 175mm dia. |

THV-T175-D | THV-V175-D | THV-C175-D |

New! Stage size φ200mm |

THV-T200-D | THV-V200-D | THV-C200-D |

Adsorption method |

Through-hole adsorption | V-groove adsorption | Porous ceramics |

Recommended vacuum pump |

Dry pumps, vacuum ejectors | ||