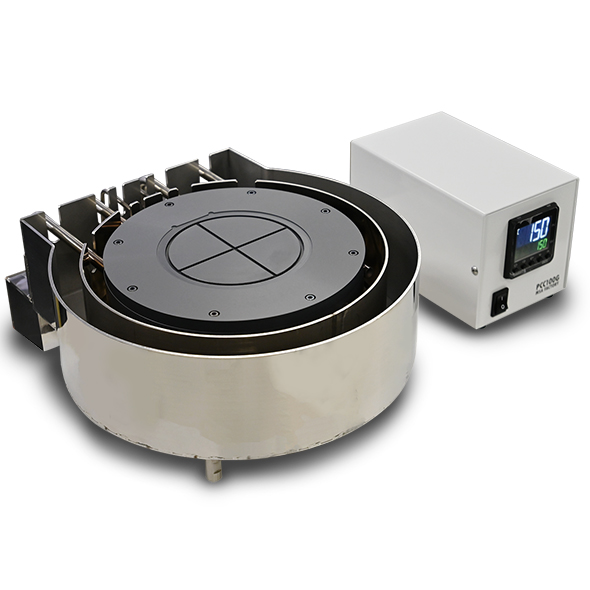

Ceramic Wafer Hot Chuck High precision and flatness wafer chuck for custom sizes up to 600°C

Wafer process (for deposition and etching processes), wafer reliability testing, and wafer characterization testing applications

Main applications

Wafer temperature characteristic test, probe mounting hot chuck, glass chuck, board electrical characteristic test

Digital Temperature Controller

Connects to MSA Factory standard temperature controller with one-touch connector. High-precision temperature control can be performed immediately with simple operation. C100_SG

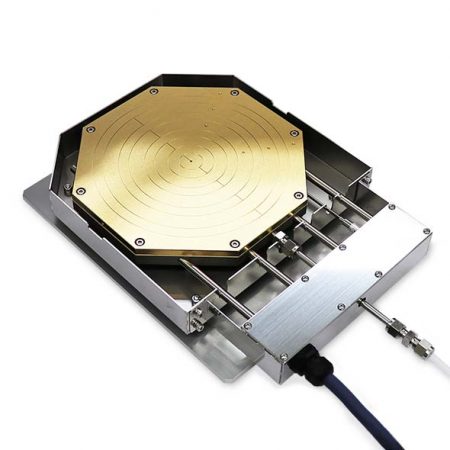

Universal zipper pattern

Standard suction pattern: If you place the workpiece in the central suction hole, the size is universal. For example, if the chuck is 6", it can be used with any size under 6", 4", 3".

ceramic

Hot chuck fabrication with aluminum nitride/AlN, silicon carbide SiC, etc. is available.

Low contamination

The ceramic base material reduces contamination on wafers and workpieces in high temperature environments.

High corrosion resistance and chemical stability

The ceramic base material is scientifically stable and highly resistant to corrosion. Excellent resistance to corrosion by active solutions and gases at high temperatures.

High precision flatness, flatness

Flatness and flatness at high temperatures are ensured by ceramics.

Chuck surface Conductive/insulating/leak

The chuck surface is available in two types: gold-plated (200°C) conductive and anodized (200°C) insulating.