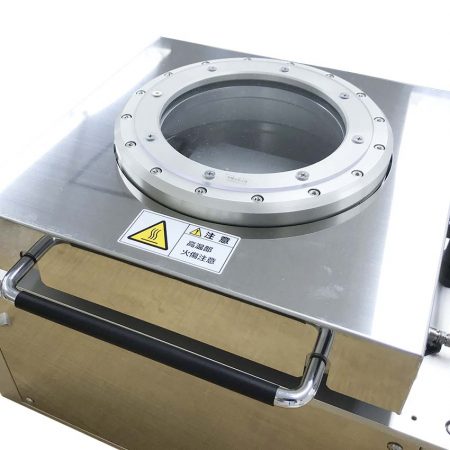

真空高速乾燥オーブン PH224Light 最高温度 200℃

主な用途

真空乾燥に特化したオーブンです。既存の真空オーブン炉より、小型タイプ、ウエハ状、薄型のワークに対して、低温度、短時間での乾燥を行えます。また、真空オーブン炉より、コストパフォーマンスが高いシリーズです。

MSAファクトリー 加熱ノウハウ

素材(超耐熱プレート、熱歪対策、チタン製シャーシ)ヒータ設計、断熱、熱輻射など様々なノウハウを結集しております。

シンプルな本体構造、コントローラにより安価なプロセス構成が可能

シンプルな本体+コントローラにより、100万円台にて、真空乾燥プロセスの構築が可能です。また、真空ポンプと合わせた構成での取り扱いも可能です。

高性能

ホットプレート加熱ですので、均一な加熱が可能です。ワークの処理時間も短時間で、従来プロセスとの時間をぜひ、比較してください。

安全性

非常停止機能、漏電検知機能、負荷断線機能などを盛り込んだ安全機能がコントローラに装備されています。

機種一覧

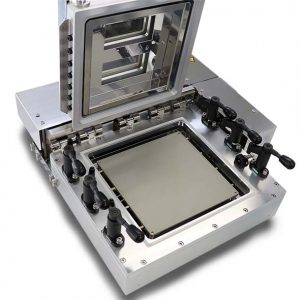

自動真空ホットチャンバー

スタンダード機種手動式バルブ操作真空ホットチャンバー